Please view these information tabs to learn more about replacing a Kieninger Clock Movement.

Assistance = 800-381-7458

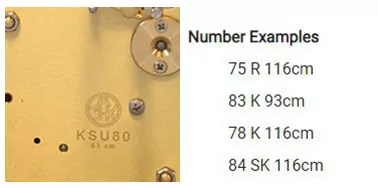

Kieninger clock movement identification

The identification process is the first step to replace a Kieninger clock movement or any other components. To begin with, start with the movement number in order to purchase a new clock movement and to see the price and what it includes.

Also, these numbers are essential to get compatible components for the clock. Examples of some components include pendulums, dials, hands, keys, cranks, chime blocks, mounting screws, weights, pulleys or chains.

Decoding Kieninger clock movements

For example, let's say the movement numbers are 81 K 116cm.

- 1981 = If it is an on older unit, the 81 would be the year it was made. On new units this number is not the year but only an internal engineering code.

- K = The K is the movement series. This is the basic raw movement plate size and internal gear configuration.

- 116CM = This is the pendulum length, in centimeters, from the top of the movement all the way down to the bottom of the rating nut. This is true only for the smallest 4 1/2 inch bob diameter.

Dating the Kieninger movement

In the above description, 81 is the date, however this is not always true in later years. After a certain date that first number is no longer the date that it was made. Rather that first number became an engineering code that has nothing to do with the date.

So it may or may not be the date code, ignore this as it is not pertinent to replacing the unit. There is no longer a solid way to date the Kieninger clock movement unless there is a stamp on the back plate.

We can help

The new movement will fit into the clock case just as the old one did. Keep using the same components such as the dial, pendulum, chime block and weights.

If it is a weight driven clock it will come with the chime hammers as well as chains or cables. If this decoding process is confusing, just email the numbers or a picture to us. We are happy to help with figuring out the best course of action. Similarly, Kieninger clock movement questions and ordering can be done by phone as well.

Kieninger Clock Movement Ordering

Kieninger clock movement ordering starts with the numbers off of the back plate of the clockworks. The numbers help us figure out the correct unit by plate size. After we get the plate size we narrow it down by attributes such as triple chime.

In other works all the units that have the letter K on the back will have the same plate size. After we determine we have a K series we select things like triple chime or Westminster only. If there are any other uncommon things after that we select it. Such as sequential or carousal or other special qualities such as this.

Steps to a new Kieninger clock movement

First go to the letter that is also on the stamp on the back plate of the movement only. If for example the movement number is 81 K 116cm ignore all but the K at first.

Find the K series on the Kieninger movement page at Clockworks.com. Then we can continue with matching up the CM in the drop down list.

Attribute selection

On that same drop down list with the CM list there are some other options usually. The options to select are the specific qualities the movement may or may not have on the movement. Such things as Westminster only or triple chime.

If there are dancers on the movement it may say carousel. Just pick the whatever movement you have that matches the options.

After ordering the Kieninger movement

After ordering the new Kieninger clock movement you will receive a receipt via email. The installation instructions will also be sent via a link on the receipt. Weight driven units will include chains or cables.

The new movement will ship the next business day by FedEx ground or Priority Mail.

New Clock Movement Benefits

New clock movement benefits far outweigh the benefits of a restoration. This section will explain why that is and what the best course of action is to get your clock working.

Servicing the movement

Clocks need to have fresh oil after 10 years or so. Then, after 20 or 30 years, a full break down of the movement is necessary. This is all well and good and can be done with the old movement.

The movement will run for another 5 or 15 years with no issues but then it will be time to do it again. So obviously this is a new clock movement benefit.

Every time the movement needs to have work done on it or needs bushings, it will last less and less time before it needs attention again. So another new clock movement benefit is that this would not happen.

The repair process is expensive because it takes time to separate the plates, remove all the gears, do the necessary work, and then put them all back together again.

This process may need to be redone if not perfect the first time. The turn around time to complete an overhaul on a clock movement could be anywhere from 1 to 3 months, and in some extreme cases, a year.

It is a slow moving venture that costs twice as much as a new movement would. If a new clock movement is not available, then this is the best, and only, way to handle a clock repair.

Replacing with a new clock movement

If the clock movement is still in production, it is far better to just get the new clock movement. Mass production makes the movement so affordable it will cost a fraction of the price of the repair work.

The new clock movement will be the same one but brand new and ready to run 30 years without much complaint. There is absolutely no way to repair an old clock movement so that it is better than new.

Even the best clockmaker using the best equipment cannot make the clock movement better than a new one.

A new clock movement is a factory fresh restart. The clock will be like it was originally when you first made the purchase from the store. The new clock movement will be made by the same people, with the same machines, and the clock movement is the same.

It is not a close replica or made somewhere else besides Germany. It is the same movement. Not a knock off or replica. So wouldn't it make sense to get the new clock movement instead of chasing the old?

The choice is clear and obvious. The new movement will cost a fraction of the price and the clock is up and running in no time.

Movements That Would Need a Repair or an Overhaul

If a new clock movement is not possible, then a repair is most likely the only option. However we will try to convert it to a new clock movement that is close and easy to adapt.

If it is not an easy one to adapt, or would take too much case work, then the best solution is to have us work on it. Another clock movement to consider having restored instead of replacing it is the tubular bell, which is a high end movement.

The price of a tubular bell new clock movement makes an overhaul more attractive. This is due to the high price on the new clock movements which is over $1600.

Usually the price is less for the new unit but instead these new clock movements are more costly than the overhaul by Clockworks anyway.

We can charge a much lower amount for the complete overhaul on these units. Ultimately the choice is yours. There is a good argument in both directions that makes sense on these expensive new clock movements.

Clockworks = The best repair service

We would love to do the clock movement overhaul here at Clockworks and we do the best job. There are two ways to fix clocks; the easy way and the hard way. We only repair clock movements the hard way with no short cuts.

Even with new clock movements, we inspect them and make sure all is well before shipping them out. It is even more important for us to do your repair than another company because we do not go to your house. There is no one being intrusive in your home and possibly damaging your clock case.

The clock movement itself is the only item that gets sent to us. No components need to be sent since we have everything else here such as weights, dials and pendulums. It is a great advantage to have Clockworks work on your clock movement for this fact alone.

A clock supply depot such as us does not need to wait for parts. We possess everything we could possibly need to complete a thorough, professional clock repair right here. If a new clock movement is not possible, then this repair is your best and only option.

The new movement

New clock movement benefits usually do indeed outweigh the repair option. The movement will already have lubrication with clock oil so there is no need to oil it.

The new clock movement comes with cables and pulleys, or chains, the leader, and suspension spring.

This is everything that comes out when you remove the two screws that are under the clock movement, besides the dial and weights.

Once you get the hands and the clock dial out of the way (instructions are sent via email) it's only a matter of removing the two screws from underneath.

The new clock movement can then be put in by someone with experience in 10 or 15 minutes. A person with no experience will take longer, but the point is that it isn't hard to do. This is definitely a new clock movement benefit.

There are some instances where a clock case was made in an annoying way that makes it more difficult, but for clock movements that were in a mass production this is not the situation. This relates more to a few individual clockmakers who's design of the case makes it more tricky to get the new clock movement in or out.

Summary of New Clock Movement Benefits

A new clock movement is typically less than half the cost of an overhaul.

It will also be on its way to the customer instantly instead of months later. A new clock movement will last the longest of any other choice.

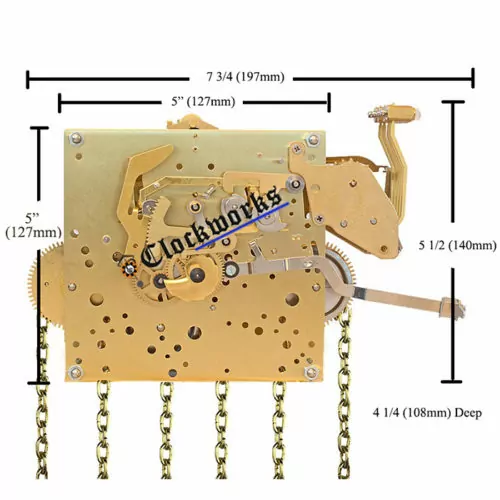

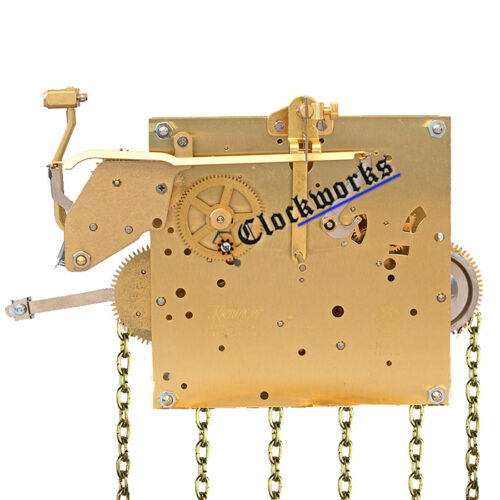

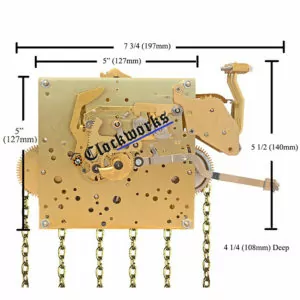

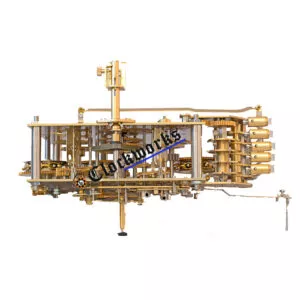

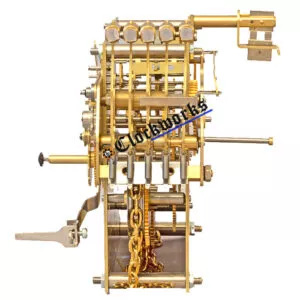

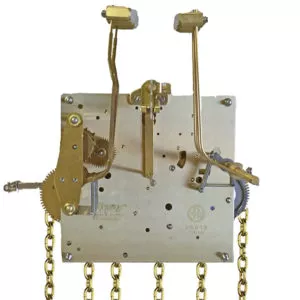

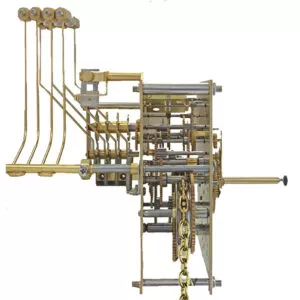

SK Series Movement

The SK Series Kieninger Clock Movement have a hand shaft length of 36mm from the front plate of the movement and all the way out. This is a Westminster unit that is chain driven.

It's use is for both grandmother and grandfather floor clock models. The unit comes in either side strike with 5 hammers or back strike with 8 hammers. This would be 4 and 4 hammers on each side.

SK Series Plate Sizing Issue

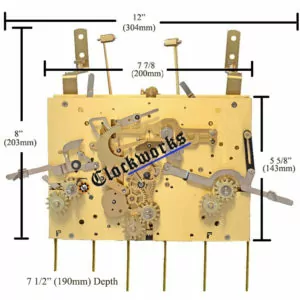

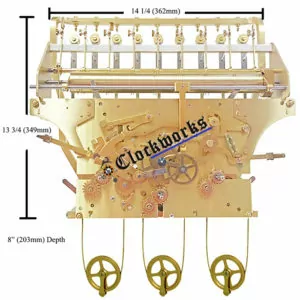

The SK Series consists of two plates with gears in the middle like a sandwich. The plate size on these units are 125mm x 125mm. The SKS unit that has a plate size of 120mm x 125mm are no longer available.

So some things would need to happen. The dial may have 4 posts that attach to the movement. These need to be cut off so the dial can attach to the wood trim. The dial cannot attacht to the movement any longer.

So if the dial already attaches to the wood trim and not to the movement itself, this is not a concern and either plate size will work the same. Furthermore, if the dial has the posts that go into the movement it is possible to cut off these posts. Simply drill the corners and use wood screws to screw it to the trim instead.

Why a new SK Kieninger movement

Replacing a movement is less costly than an overhaul. The SK Series Kieninger Clock Movement lasts 25 years before needing an over haul. But since its still being made at a fair price it is so much better just to replace it. There is no way a repair can get better than a new unit.

The SK or SKS movement will be problem free right away instead of months and it will last longer than an overhaul. It also comes with oil in key wear areas so it is ready to run right out of the box.

What the SK Series Kieninger Clock comes with

This high quality SK Series Kieninger clock movement comes with oil in key wear areas and includes its chains, leader, suspension spring and hand nut. The movement will have removal and installation instructions and our support.

Kieninger movement decoding

An older Kieninger clock movement will have the date first, then the series "SK or SKS" and the CM length on the back plate of the movement. Such as 83 SKS 116CM. However the first number on in the later years was no longer a date code and more of an internal code for the factory.

Movement removal and installation

Removal is easy and we provide instructions for the installation. This SK Series Kieninger Clock Movement is in stock and can ship today. We are both full time clock makers and retailers. So if you need any assistance with the install we can help.

We have a Howard Miller clock model #612-485 that has a clock dial that needs to be replaced. We also need the fiber board that goes underneath the clock dial and attaches to the mechanism. We have your new Kieninger model # PS -37 to attach to the clock dial. Our old clock dial is causing the second hand to not function. We would appreciate any help that you could give us in this matter.

Can I see some pics of the dial, how wide is it, why is the second hand rubbing

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

Howdy, sorry another question. My Kieninger PS-37 is a cable driven clock. I have removed the mechanism. When I put tension on the cable that runs the time movement, not the gong, and manually move the pendulum crutch, the clock will tick, that is the escape wheel turns as it should. Why with the movement installed and the weights hung and pendulum afixed does it not work?

Sounds out of beat. Put in beat as described here

https://www.clockworks.com/posts/mechanical-clock-movement-beat-setting

Be sure cable is not rubbing anything on its way down, be sure cable not crossed or jumped ship off its spool. |

Pendulum not rubbing anything, bob not bonking the sides of the case, put in beat, run with no hands or dial at first

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

Howdy! I have a Kieninger PS-37 mechanism. Installed it in my clock case, hung pendulum and weights. The escapement does not work. On the right swing of the pendulum (right facing the clock) the escape wheel clicks forward, but on the left swing, it is not engaged and snaps back to its original position. Is there anything I can do/check to see what is wrong before returning the mechanism?

All mechanical pendulum clocks need to be put in beat to run. No putting in beat = will never run.

See instructions again at this link

https://www.clockworks.com/posts/mechanical-clock-movement-beat-setting

Instructions

https://www.clockworks.com/spring-driven-clock-instructions.html

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

I have a morning sks15 the chain on the strike train come off and let’s the weight fall. What is wrong with this? It does not do this very off but when it does it break the bottom of the case.

These are good units that last typically for 25 years. But when they break, this is the part that breaks. Always the ratchet wheel on the SKS goes wrong. There are no new ones to get, and even if there was the movement would need to come out and be taken apart to swap it. We are left to order the new movement, so we are good for that much longer again in the future.

Please order the SKS from this link

https://www.clockworks.com/product/new-sks-series-kieninger-clock-movement

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I recently purchased your KIEN SKS-15 to replace my SKS-13 which had a defective cog wheel. I have replaced the movement in my Howard Miller Grandfather clock (model #610-520). My only problem right now is that the pendulum does not keep swinging. I have 2 heavy weights which are on the right side and middle. The pendulum bob is 6.5″ round with the lyre on top and is at the same distance from the movement as it was for the SKS-13. Is there any help you can give me to determine why the pendulum does not continue

swinging.

If the chain driven clock will not stay running please check these items

Is the pendulum touching anything at all or the sides of the clock case

Is the pendulum rubbing the chime rods at all

Are the clock hands touching each other or rubbing the dial

Is the moon gear meshing ok with the gears on the back of the dial

Is the chain dropping directly down through the seat board, not rubbing the seat board or the mounting screw

Is the crutch, the part that wackes the pendulum hanger back and forth, able to wack it ok? In other words the leader

(pendulum hanger) is going directly through the crutch, not riding the back of the crutch or front of the crutch but in the middle so the crutch can wack the pendulum hanger just a bit during its tick / tock

Is the clock in beat? This is the most common issue

Putting a clock in beat

In many cases the complaint with a mechanical clock is that it stopped working after it was moved. This is usually from someone moving the clock without taking the pendulum off and this puts the clock out of beat. Out of beat is a term used in clock repair that basically means the clock is going tock-tick tock-tick instead of tick tock tick tock. It is sometimes corrected by putting a matchbook or Small piece of wood under one side of the clock case to make the tick and the tock evenly spaced. This can temporarily correct the problem and the clock runs fine.

This method however is not as good as correcting the beat and having the clock run when it is truly straight and level. This can be done on most clocks by slightly pushing the pendulum one way or another beyond its resistance to far to one side. This will affect the tick and tock and the idea is to get this to be evenly spaced in time as in tick tock tick tock,

not ticktock ticktock, or even tocktick tocktick

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

What a great website thank you clockworks!

Great Job –

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

beautiful clock, purchasing now.

It is indeed! Thank you for your order 🙂

I have a Harold Miller Jonathan grandfather clock WITHOUT a pendulum. Movement is model SKS12 Keininger..I would like information for ordering a new pendulum.

Hi

Please order a lyre style pendulum for a Kieninger 116cm clock movement from the link below.

The bob diameter would need to be selected, This is the round disk at the bottom of the pendulum.

https://www.clockworks.com/product/kieninger-lyre-clock-pendulum

The bob diameter needs 2 inches on each side to swing back and forth, so the inside case width would need to be wider than this. So if the case is 12 inches wide on the inside, the maximum bob diameter would be 6 1/2 inches wide for example.

Or please order the wood stick pendulum in the same way from this link

https://www.clockworks.com/product/wood-stick-pendulum-for-hermle-clocks

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a SKS13 116 cm 354 499 movement from a Howard Miller 2001 grandfather clock, Westminster chime, side hammers, with moon dial. But I don’t know what plate size it is, and don’t know how to measure it. Which Kieninger movement is best?

Please measure the back plate of the movement itself, it will either be the wider one or not. It is only a matter of if the dial posts will match up with the holes drilled into the front plate of the clock movement or not, this is the only difference as far as installing or running the clock. IF the dial is attached to the wood clock case instead of to the movement will the posts, it does not matter what one is purchased

James

What movement would I need to replace a SKS13 116cm 354574 in my Howard Miller clock

It would be this link

https://www.clockworks.com/product/new-sks-series-kieninger-clock-movement

and side hammer option.

However the SKS13 has two plate sizes, if not getting the right one, the risk is the feet on the back side of the dial, that lock into the movement, will not match up.

If the dial is attached to the wood case and has no connection to the movement, it does not matter as much.

James

I have SKS13 116 CM 354-499 movement in a grandfather clock. It has the big pendulum. Can I get a replacement movement. The center weight drops to the bottom of the cabinet sometimes.

Hi,

Sounds like the ratchet wheel on the time train of the clock movement has become defective. This does happen over many years of service by the Kieninger SKS series clock movement, after about 25-30 years. I do believe that one has the smaller plate size, but please verify this fact. You would measure the back plate of the clock movement itself, only the big plate that holds all the inner gears in the gear sandwich. After that you can select from the options on this same page to get the correct movement. Keep in mind these are no longer made, and when stock is gone there will be no more at least for a while. We have only 2 of the SKS13 left in stock at this time.

James

Hello,

I recently acquired a Howard Miller the SKS13 Movement with the weights dropping. I split the Movement plate (the sandwich), removed the ratchets (3) disassembled them, filed the gear slots out where the spring plate finger drops in the slot and flipped the gear, assembled and assembled the movement, all 3 work great. On 1 of the ratchets, the spring plate with 4 fingers was broke off- only 2 at a time drop in the gear slots. Hope this help if someone cannot get parts.

Yes needs a ratchet wheel but there are none separate from the new movement to offer. Best to order the new SKS15 with the larger plate size and be sure the movement is attached to the wood case trim instead of to the movement itself, from this link

https://www.clockworks.com/product/new-sks-series-kieninger-clock-movement

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Quality movement!

I have SKS13 116 CM 354-499 movement in a tall Howard Miller grandfather clock. My mover lost one of the weights. I have one weight that says left on it, and the other weight is quite heavier but with no label on it, and I’m missing the 3rd weight. I’d like to get this clock going again. Any help on identifying what weight I need to buy?

Hi

Clock needs 1 weight at 4.7LBS and two weights at 6.6LBS from this link if the pendulum bob is 8.5 inch or more.

https://www.clockworks.com/clock-parts/clock-weights.html

Clock needs 1 weight at 6.6LBS and two weights at 4.7LBS from this link if the pendulum bob less than 8.5 inch wide

https://www.clockworks.com/clock-parts/clock-weights.html

The heaviest weight would go on your right as you face the clock.

The lightest weight will go on your left as you face the clock.

The middle is light or heavy depending on the bob diameter.

(The larger bob diameters require more weight in the center.)

what movement would replace the 610520 354629 MVT WST CH SK/116CM KIENINGER movement

From the information you have provided here is the replacement unit:

https://www.clockworks.com/product/new-sks-series-kieninger-clock-movement

To confirm and be sure please send a photo of the front and back plate of the movement to clockwork.com

Thank you !

Clockworks Team

That one is the Kieninger SK series from this link

https://www.clockworks.com/product/new-sks-series-kieninger-clock-movement

James