In many cases the complaint with a mechanical clock is that it stopped working after it was moved. This is usually from someone moving the clock without taking the pendulum off and this puts the clock out of beat. Out of beat is a term used in clock repair that basically means the clock is going tock-tick, tock-tick, or ticktock, ticktock instead of tick tock tick tock. It is sometimes corrected by putting a matchbook or Small piece of wood under one side of the clock case to make the tick and the tock evenly spaced. This can temporarily correct the problem and the clock runs fine. This method however is not as good as correcting the beat and having the clock run when it is truly straight and level.

This can be achieved on most clocks by slightly bending the verge one way or another. The verge is the only movement part that touches the pendulum and whacks the pendulum back and forth.

The verge is what gets bent or pushed when the clock is moved, without taking the pendulum off the clock. A verge that is pushed or bent effects the escapement of the clock; the escapement being that part of the clock that actually creates the tick and tock sound.

By bending or pushing this verge back into position, and then listening to the sound, you can make the clock go tick tock, tick tock rather than tock tick, tock tick or ticktock ticktock which means the clock is in beat. This method is the same for most mantle clocks, kitchen clocks, grandmother clocks, and grandfather clocks.

If the clock is now in beat, meaning the tick and the tock are evenly spaced, but then the clock stops after awhile, what now? Here are some other common ailments that are meant to be looked into before going into a cleaning procedure. Are the hands touching the dial, or each other? Bend the hands so they do not touch.

Is the pendulum touching another object during its swing? The Weight Driven Clocks pendulum cannot touch anything during its swing. It is commonly found in mantle clocks that the wrong pendulum bob has been put on the clock. Bobs are lost frequently like clock keys. If someone decides to replace the bob but hooks on a fatter one then the original, it may bump into the movement during its swing, even though the clock is level. Being off level is the most common reason for the pendulum to be blocked during its swing. If a clock is not level side to side and front to back, (or close) the bob may hit the case. It depends on the clock. All clocks are meant to be level and in beat from side to side, but not all clocks are meant to be perfectly level from front to back. The point is, to keep the pendulum totally free from obstructions because it uses its own weight and momentum to help keep the clock running. If it bumps anything, even slightly, then it loses some momentum and the clock will eventually stop.

If these things do not fix the clock then it would be safe to assume there is a general lack of power in the time train. It is time to give the Weight Driven Clocks clock a good cleaning and check it over for excessive wear. If the old oil dried up, then this would cause too much friction for the clock to run with the weights power. Clean out the old oil and check for excessive wear at the pivot holes. Pivot holes are explained in another section.

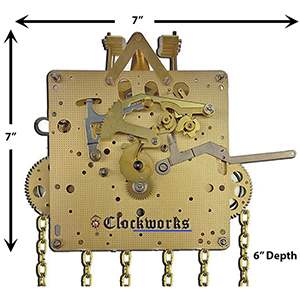

To get to this point means it is time to look for a New Weight Driven Clocks Movement. Unless you find clocks as interesting as I do, then the time required to overhaul the movement is not worth it when you can get a New Movement, improved by the factory with bronze bushings, which will be more cost effective. It can be much more expensive to overhaul a movement because of the extensive time it takes to disassemble the movement, work on it, and then put it all back together again. Forget about the movement being sentimental when it comes to replacing it, keep the case sentimental, not the Weight Driven Clocks movement. If the movement is on our charts, then it is best to replace it.

If you do not hear any tick tock from a mechanical clock, even if the verge is moved back and forth by hand, this means there is a big obstruction in the way of the mechanics of the movement. This could mean any of the following:

1.The hands are touching something, bend the hands to freedom.

Clock Hands

2. The chiming mechanics are out of synchronization and they are doing something to stop the movement. If the chime mechanics seems to be your clocks situation, it is recommended to read up on these parts with our E-Book.

NOTE:

There are only two general methods that a clock synchronizes the chime with what hour it is, these two methods are called Rack and Snail or Count Wheel. Both of these involve many interactions between the arms inside the movement (The arms are in the front of the movement in a rack and snail style movement).

Rack & Snail movement

3. The weight chain or cable is pinched or hung up somewhere. This can happen during the installation of a Weight Driven Clocks movement to its case. See if the chain or cable is rubbing anything or getting pinched anywhere.

4. Star cam not aligned correctly. These are the two star like looking gears that are on the outside of the Weight Driven Clocks movement plates. One slips over the winding arbor and one is near each winding arbor. Not all clocks have these, but for the clocks that do, it can be tricky to get these correctly aligned if

The only way these can get misaligned is to remove them, so if the winder arbors were NOT removed from your clock movement, this would not be your reason for stoppage. (winding arbor = the arbor with the square end that the key goes on) Now for the people who did have the winding arbors removed, let's first explain what the purpose of these stars are and then how to install them correctly so we can get some ticking out of the clock.

These star like gears have a purpose of not allowing the weights to go to far up or down. If you look close at them you will see there is one tooth that is longer than the rest on the winding arbor star gear, and one tooth entry point that is not as deep as the others in the other star gear. These gears work fine until it gets to the point where the tall tooth hits the short hole and this stops the clock. It does this to do two things: not let the clock get so wound up that the weight and chain attachments go into the movement; and it also stops the weight from dropping too low during running, where it will hit the clock case bottom or run out of chain so it falls to the bottom.

These can be removed completely and not reinstalled if you choose. Just don't wind the clock weights up so high the chain or cable gets caught up in the movement. Risk being the weights end up at the bottom of the clock case about the ninth or tenth day and you risk the opposite end of the chain getting stuck in the movement. The fix for the star cams is not that bad, so you might as well put them on as your supposed to.

Just wind up the clock to where you would like the weights to hang at full winding, while you watch the action of these star gears. Then install the gears so they lock at that spot while the clock is being wound up. At this spot there should be plenty of room for the weights and its attachments to be free from touching anything, and the clock not too top heavy that it will fall over on someone when the door is opened. That's it, its done, the lower side will take care of itself and stop in 8 days like it should

This section is for the clock that chimes at the wrong time, or chimes the wrong amount on the hour. This usually happens when the clock is laid down on its back and then later put back upright and attempted to run again. It is easy to fix.

NOTE:

Understand these two points first before proceeding: Some Weight Driven Clocks clocks do not like it when the minute hand is turned counter clockwise, so for the beginners, just go by the rule that all Weight Driven Clocks clocks should only go clockwise with the minute hand and you will be safe. In fact most clocks you can go backwards just fine, they are designed like this so it is okay, but to be safe for the sake of the few that can not go backward, go forward only. Also understand this one other point; on just about all clocks, with the exception being newer Japanese clocks and 31 day clocks, the hour hand is only a friction fit and can be turned on the hour tube to any position on the dial, backward or forward. If the hour hand becomes loose during this, just push back on its tube and it will be tight again. Now that you understand those two points, to move the minute hand forward only and the hour hand is usually only pressed on being a friction fit, we can continue setting the clock chime.

To correct a mantle or wall clock that is bonging the hour when the minute hand gets to 6 o'clock instead of 12 o'clock, just count the bongs, take off the minute hand and reinstall it on the clock pointing to 12 o'clock, then turn the hour hand to the hour you heard the clock bong and its done. To correct a clock that is bonging the wrong hour on the hour, just turn the hour hand to the correct hour the clock bonged, then reset the time correctly with the minute hand letting it bong as you go. Your done!

This section is for Weight Driven Clocks Westminster or other 15 Minute melodies not chiming the hour, on the hour. If the clock is chiming prematurely only about 5 minutes or so before it is supposed to chime, on most clocks you can just take off the minute hand and turn the bushing that is in the center of the hand one way or another so it is exactly on the hour when it bongs its melodies. If the clock chimes the first quarter when it is supposed to be chiming the hour or something similar, just remove the hands and put them to the time that it is bonging.

NOTE:

On many quarter chime clocks, they have a self correcting feature and you should wait until a couple of hours go by after setting up the clock, to see if it will correct itself. There is a short cut to this, simply go around once or twice with the minute hand, letting it bong as you go. If a hour or two has gone by and the clock is still singing the wrong song at the wrong time, then remove the hands as stated earlier and put them to what ever time the clock is bonging, then reset the time with the minute hand.

Cleaning without disassembly is not as effective as breaking down the movement, but it is sufficient in most cases. Not everyone is ready to break down their clock movement and put it back together. We offer a Basic Clock Cleaning Kit that is for the person who would like to do a simple clock cleaning without having to learn an intense amount of clock repair. The goal to cleaning a clock movement is to remove old oil that has solidified and put new oil in its place. Solidified clock oil creates wear to the movements outer plates and eventually causes too much friction for the Weight Driven Clocks to run.

Disassembling and reassembling a Weight Driven Clocks movement for a cleaning is a job that takes patience and some time to learn how the movement operates. If these are not things you wish to invest, it is best to get a New Movement from our charts that would fit your dial, pendulum, weights and chime rods, they are usually in stock and ready to ship.

If you are willing to learn how your Weight Driven Clocks operates, and would like to clean and repair the clock yourself, it is best to start out with the simple kit we have put together for this purpose. It includes The Clock Repair E-Book that guides you through each step of this process and explains the striking components so you can reassemble the movement and have it strike correctly. You need the E-Book to assemble a striking movement. This E-Book is included in the Basic Clock Cleaning Kit. You get the clock cleaning solution, the E-Book, a brush, a clock level, clock oil and a vision visor. The E-Book explains what to do with these items.

There you have some options, get the Basic Clock Cleaning Kit and start reading up on how to clean and oil your Weight Driven Clocks movement, or just replace it with a brand New Movement. You can start with seeing if the Weight Driven Clocks movement is available, and if it is then try the clock cleaning kit and see if you can get it to work on your own before making the new Weight Driven Clocks movement purchase.