Quartz Clock Movement Removal

This note explains quartz clock movement removal from the case. The following does not apply to quartz units made in Germany or inserts.

To remove the movement, you need access to the back of the clock and the front side of the clock dial. There are so many case designs it would not be possible to cover all of the different variations.

The clock case went to together so it comes apart. It may take a bit of probing but there is always a way to take it apart because it went together.

Getting access to the dial area

There are many case designs and styles and there is no way for us to know how the current specific clock went together. Most of the time the removal process is very easy but of course there are some instances where it is not user friendly.

Thus, it is on the users end to be able to access the dial and movement area to continue with the swap out.

Clock hand removal

Quartz clock movement removal always needs the hands to come off first. There are two reasons for this.

First, need to have access to the hardware that mounts the movement. Second, there is no way to take get the movement out of the clock if the hands are still on it. They certainly will not fit through the hole in the clock.

Quartz Clock Movement Removal - Minute hand

Quartz clock movements have two styles of minute hands. One style has a nut that holds it in place and the other style is a friction fit.

The friction fit has no nut and just pulls off with a twist and pull. The second style has a minute hand nut to secure the minute hand. Removal is done by turning the nut to the left with needle nose pliers. Once the nut is loose it only requires fingers to unscrew it.

Hour hand

In a Quartz clock Movement removal task, the hour hand is only a friction fit. Thus, the hour tube tapers down on the movement, meaning it is wider on the low end of it.

This makes the hour hand friction fit only. Just twist the hand and pull it until it comes off.

Second hand

The second hand pulls straight up and off if the clock has one.

How to Install a Battery Clock Movement

Welcome to our comprehensive guide on installing a battery clock movement. Whether you're a seasoned clock enthusiast or a novice DIYer, this step-by-step tutorial will help you breathe new life into your cherished timepiece.

To begin, let's address the removal of the old clock movement. This process can vary depending on the design of your clock. Start by carefully removing the hands from the clock. In some cases, you may need to remove a glass bezel to access the hands. Once the hands are off, locate the hex nut securing the movement to the clock dial. Remove this nut to release the movement.

Occasionally, the movement may be secured with glue. If so, gently pry the movement off the back of the clock using a screwdriver.

Now that the old movement is out of the way, it's time to install the new quartz clock movement. Clockworks offers a variety of high-quality quartz movements suitable for different types of clocks.

Quartz clock movement installation is typically straightforward. Follow the sequential order of installation outlined below to ensure a successful upgrade:

Sequential Order of Installation

- 1. Place the steel hanger over the post with the threads (optional)

- 2. Place black rubber washer on the post next (optional)

- 3. Start mounting the movement by putting the post through the dial

- 4. Then on the front of the dial, slide the brass washer onto the post of the movement.

- 5. Put the hex nut on post and tighten so it holds the movement to the back of the clock face.

- 6. Push hour hand on the post by friction fit

- 7. Put the minute hand on the post

- 8. If using a second screw the doughnut on to hold the minute hand in place. Then install the second hand now by friction fit. The post just sticks onto the pin at the end of the post.

- 9. If not using a second hand just secure the minute hand with the pretty cap nut.

The Movement Installation is Now Complete

Naturally, this guide applies to all clock movements that take a battery, available on Clockworks.

For example, Clockworks offers a variety of options including chiming quartz, time-only, and high torque movements. However, clock inserts are an exception.

Additional Tips for Successful Installation

When installing a new battery clock movement, ensure that all components fit securely and are aligned properly to avoid any issues with timekeeping or functionality.

Before tightening any nuts or screws, double-check that the movement is correctly positioned within the clock case to prevent misalignment.

If you encounter any difficulties during installation, refer to the manufacturer's instructions or seek assistance from a professional clockmaker.

Quartz clock movement measuring

Please select the post length when ordering a new quartz clock movement. Of course, when doing quartz clock movement measuring, remember the post will need to be able to go through the thickness of the dial face.

Also remember that the dial may or may not have a wood backing to it. With a wood backing the clock dial or face would be thicker and thus would need a longer post.

Clockworks offers multiple post lengths on quartz clock movements for this reason. In other words, the post has to be long enough to go through whatever thickness we are calling the dial.

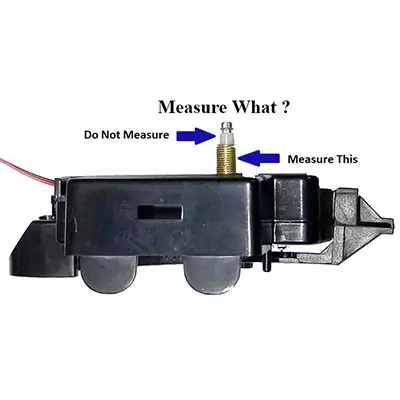

What to measure

Clockworks offers multiple post lengths for quartz movements. When completing a quartz clock movement measurement, you will need to measure the post on the old movement.

This is so it can match up with the new quartz movement. To clarify, the post is the part that goes through the dial (face) and mounts from the front and what is in a quartz clock movement measurement.

This applies to all Clockworks quartz movements, including chiming quartz, and time only quartz movements.

Length depends on dial thickness

When working on a quartz clock movement measurement the post has to be long enough to go through whatever thickness that the clock face/dial, might be. The length of the threaded portion of the post/shaft, is the measurement that you need.

The shaft with the threads needs to go through the dial/face of the clock from the back to the front. It needs to be long enough for a small hex nut to screw onto it. It can’t be too long or the hands will not move correctly.

Clockworks has a variety of quartz clock movement lengths to accommodate a variety of different materials since some are wood and some are metal and some are plastic, etc.

Measuring quartz post lengths

Above all, when replacing a quartz movement it means measuring quartz post lengths. Subsequently, the post will stick out through the front of the clock dial.

Of course, there needs to be enough threads sticking out for the hex nut to be put on. Hence, the movement will be held in place to the back of the dial (clock face) and will not move. Sometimes if the clock has glass over the face it is possible for the post to hit it.

Therefore it is important to measure the quartz post length correctly. In other words, if the post hits the glass, the hands will not be able to move. Thus making the clock not work.

Use the chart if building a clock

With that being said, find the correct quartz post length by using the chart below. So remember, the threads on the post need to be at least 2/16 longer than the thickness of the clock dial.

To clarify, a clock dial is the face (also known as the thing with the numbers on it). As always, email us if there is any question.

Measuring quartz post lengths if replacing a clock

If replacing a movement and not building a clock, it is easier to measure the quartz post length of the old movement.

Before measuring, remove the movement first by taking off the hands and then the hex nut. Next, measure the length of the post that has the threads that the hex nut was on.

In short, only measure the fat part of the hand shaft that we call a post. Also, never include the part that the hands go on when measuring the post length. All in all, the new unit needs to be the same post length as the old movement.

Overall, this applies to all quartz clock movements available on Clockworks such as chiming quartz and time only quartz.

Dial Thickness

- 1/16 inch thick

- 3/16 inch thick

- 5/16 inch thick

- 9/16 inch thick

- 3/4 inch thick

Size Post Needed

- 3/16"

- 5/16"

- 7/16"

- 11/16"

- 15/16"

Pendulum Drive

This is a heavy-duty battery unit that can swing almost any mechanical clock pendulum. Tested with 2lbs 8oz (1100 grams), 44 inch long metal lyre pendulum with 8 ½ wide bob. Uses only two C cell batteries and is very strong. The main swinger part measures 5 1/2" x 2 5/8" x 2".

This item mounts to the back of the clock case. Moreover, it is just meant to swing a pendulum. To run the clock, please purchase one of the movements.

I am trying to repair an antique clock for a lady I go to church with. I’m having problems because I need battery unit that has a 1 inch set back to be able to swing the pendulum. Will what I have in my cart work and is that all I need? If I could talk on the phone with someone I would appreciate it.

Please call 800 381 7458 and press the extension for quartz

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

How long do the batteries last for the pendulum drive?

2 years?

Depends on a lot of things

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

Does the pendulum start on its own when batteries are inserted? Aka no need to swing it to start?

Yes swing it

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

I have one 8 Days Music Dancer Cuckoo Clock Baroque Design (https://www.cuckooclock.eu/8-Days-Music-Dancer-Cuckoo-Clock-Baroque-Design/8023 Tomah).

This clock breaks down from time to time and sending it for repair everytime is expensive and time consuming.

Can this clock be converted to battery operated but preserving the exterior dial, hands, pendulum and the dancing figures with the actual cuckoo? Can the weights be kept for show? Will the music and the chime work?

Will you help me with a battery model or combination of models that can convert this clock to battery operated?

Sorry only have parts and movements for the mechanical cuckoo clocks and movements

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

can you adjust the speed

Not really but some put duct tape over the magnet if it is too much of a swing

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Most sites that sells the heavy duty pendulum drive motor made the same as yours states that the weight capacity of the pendulum is 350g does your pendulum drive motor have a different pendulum drive that allows it to carry 1100 g. Pendulum?

It is what we tested here, with the actual product.

Tested with 2lbs 8oz (1100 grams), 44 inch long metal lyre pendulum with 8 ½ wide bob.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Is there a particular battery powered movement with chime for a floor clock (grandfather) that would be recommended to go along with this pendulum drive?

Although any quartz movement will work to keep time, this one has the best sound

https://www.clockworks.com/product/premium-chime-clock-movement

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Will this work with a 12-inch clock pendulum?

Yes

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hello! I added 2 ounces of weight, no change. This seems weird – it works fine if the bob is above midpoint on the shaft. Here’s a link to a video of the jitter:

https://photos.app.goo.gl/A4Enkmcjjqi1PKTWA

That looks so weird. Not sure, but I bet it has something to do with the bottom of the pend drive not being supported. Maybe it is best to test it will the drive attached to a wall or back of the case instead. If fails Ill send a different one out

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Update, the pendulum shaft is 41 inches long, and weighs only 4.5 ounces..

Sounds like a good length, please try more weight on the bob and see if it helps

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hello! I am building a grandfather clock, and I get serious jitter with this pendulum drive when the pendulum is below the midpoint on the pendulum shaft. It works ok when it is high. Any Ideas?

Not sure what is meant by jitter, please explain

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

do you have a pendulum for this, 18″long and 4.5 ” dia. disk gold color?

Yes no problem please call in your special order to the mechanical line 800 381 7458

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Will the heavy duty pendulum drive require setting or will it adjust to the size of the cabinet?

Settings? No. Pendulum will swing, if it swings too much some use duct tape over the magnet to slow it down some

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Just reading the comments and figured I would chime in and ask if the spacing and placement of magnets could cause this because both have stated they are messing up when the ball is at the bottom wich could be causing the plastic to move in the video it looks like the bottom magnets were closer together then the top also looked to me like one of the to might have also had some slope to it

Do you think this would work for a pendulum that weighs about 10 pounds? Thanks.

no, too heavy

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Thanks. Just to confirm, you don’t sell any drives that could accommodate heavier pendulums, right? I’m converting an old grandfather clock, and the pendulum is heavy. Thanks again.

Correct

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hi, I am having a strange problem. The pendulum stops, then starts again after a day or so. I dont touch it, or change the batteries, it just starts going again. It has been cycling like this for a year or so, every few days it stops, then starts again. The batteries are fuily charged. Any ideas why this is happening or if there is a way to fix it?

Do not know the answer. That is a strange one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I noticed the mechanism holding the pendulum can be moved front to back. It was all the way forward, so I pushed it as far back as it would go. The magnets seem to line up better, and perhaps is more level. I haven’t had the issue now for 2 weeks.

Great job !

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

So I bought the heavy duty pendulum drive, my bob is 4″ the length with the wooden shaft is 28″ and the case it is swinging in is 8 1/2″. However it hits both sides when everything is leveled perfectly.

If the HD pendulum drive works too well and thus the bob hits the sides, some put duct tape over the magnet to lessen the force its swinging. Or swap the bob for a smaller one.

Hi,

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Is there one product that is a quartz movement and can handle a heavier pendulum?

Hi,

No, the external drive such as this, will run the heaviest pendulum

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Is this product returnable?

Returns:

For orders over 20.00 that need to be returned or exchanged please make sure you send it with a note. Sometimes we get things back with no note, and we do not know what to do with it, so please be sure to include a note with your contact information, invoice number and what products you would like for an exchange or if you want a refund. You do not need an RMA number.

Any items that are returned for credit valued over $20 will incur a 15% restocking fee.

Exchanges will incur a reshipping charge. This will be submitted to the same form of payment.

No merchandise may be returned for credit or exchanged after 30 days.

There are no refunds on regeared mechanical clock movements, these custom jobs are for one customer and cant be resold.

There are no refund on shipping charges.

There are no returns or exchanges for orders with product value under $20. Reason = Other retailers usually charge a small item fee of about 5.00 to 10.00, we do not do this. Instead we do not offer refunds or exchanges on orders valued 20.00 or less. We explain everything in detail within the product pages. The explicit instructions are there so that you can order the correct item. It is time consuming and very expensive to keep reshipping and swapping mini movements, keys, etc. Please be sure to read the instructions thoroughly before making any decisions on what to purchase. If you have any questions or concerns after reading the instructions thoroughly, please send an email to clockworks@clockworks.com and we will be more than happy to help you. We want you to order the correct thing the first time around and get your clock up and running!

Excellent experience with the heavy duty pendulum converting my grandfather clock to battery powered movements. Sharing my experience: when I first mounted the movement it did not work because it would not maintain the swing. I moved the Bob down 4 inches hoping to increase the momentum. That worked and the pendulum has a nice wide swing. Missing the TikTok I placed a small ”Sharp” battery quartz alarm clock behind my clock. It’s quartz TikTok sound aligns perfectly with the swing of the pendulum. The whole combination has given new life to our centuries old grandfather clock!

Great job Bob !

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Is this just a pendulum swing unit or is a movement also.? If also a movement, chime or music?

Pendulum swing unit only, movement sold separately

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I connected a 6oz, 36-inch pendulum to your Heavy-Duty Pendulum Drive. The pendulum hangs on the drive but the joint is somewhat flexible rather than being a rigid connection. When started, the drive operates at about the same speed as if there were no pendulum and the pendulum wants to move at a much slower speed. How do I correct this? You can see a 5 second video of the problem here: https://www.amazon.com/clouddrive/share/tjBW5YJvTKcEH5ZW2gcnAcJ9QVvoJZ5X3YK1iKXYrYw

Hi,

I am not sure. Did you stop it from swinging completely up top, then give it one good broad swing?

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Yes, I tried that. Have you seen anything similar to the video that would offer a clue? The pendulum hangs from the drive mechanism and the joint isn’t rigid. I don’t want to start bending the pendulum hanger unless someone with experience thinks the lack of rigidity could be the problem. But, I’ve invested a lot of time making the case so I need to find a solution.

If you got it from us just reply to your receipt by email and say its defective

We will swap it out

James

I made a “splint” using a popsicle stick held in place by small diameter wire wrapped around the pendulum and the drive hanger. This made the joint rigid and it’s now been running almost a couple of days. I think the permanent solution will be to crimp the hanger onto the pendulum with vise grips when I get to the final assembly stage of the process.

Great job, if it works so be it. If the drive needs to be swapped out please just let us know.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Will it carry a 36 inch pendulum.

YES

I need a pendulum drive for a large wall clock. The pendulum is 17.5″ long and weighs 14-7/8 oz (423 grams). Would your Heavy-Duty Clock Pendulum Drive be sufficient for this application?

Yes it would be perfect

James

What is the depth of this heavy duty pendulum drive?

Clock doesn’t chime. It’s battery operated , the battery box that runs the pendulum was somewhat rusted an was missing the contact spring that holds the battery in it. No sound at all is coming from it. What do it get to replace that?

For Time Only movements (No chime, No pendulum) See this link

https://clockworks.com/clock-movement/quartz-clock-movements-time-only.html

For High Torque movements that are time only (No chime, No pendulum) See this link

https://clockworks.com/clock-movement/high-torque-quartz-clock-movements.html

For Chime Movements or Pendulum Movement See this link

https://clockworks.com/clock-movement/quartz-specialty-clock-movements.html

Yes…I posted a week ago that my heavy duty pendulum drive would continually swing my 7.2 oz. original grandfather clock pendulum….but….after switching the bob to a 2.7 oz bob and the fifth attempt…it has been swinging for over a week…I’m ecstatic….yes, I previously removed the new batteries and checked them with a battery checker, made certain the unit was perpendicular to the floor, jiggled wires (hoping for a bad connection) etc..but it just wouldn’t work until my fifth attempt and has been working ever since…..gremlins? I don’t know, but I am now satisfied with the unit….

Will this pendulum drive unit work with a shelf clock case about 12-13 in high?

It could be too light, that is the bob itself is too light. It needs a bob with some weight for the momentum.

James

I had my post removed….why…..the heavy duty pendulum drive will not swing my 25 inch pendulum rod with a 2.3 oz. bob and brand new “C” batteries….;

Craig, we will certainly send out a replacement for that defective one no problem. Please just email us the order number, and the issue.

James

When will this item be back in stock?

We ran out of them, they should be restocked in 2 days.

James

Now in stock

Can the heavy duty pendulum drive be mounted below the centerline of the dial face in order to shorten the pendulum stick and shorten the bob swing?

The HD pendulum drive can be mounted where ever you like in the clock case, as it is independently mounted from the movement

James

Will a 3-1/2″ diameter pendulum bob have adequate swing clearance inside an 8-1/2″ wide case at a 22″ to 24″ swing length?

Yes that is fine

James

Will a 3-1/2″ diameter pendulum bob have adequate swing clearance inside an 8-1/2″ wide case?

Yes will work very good.

James

What is the tip to tip length of an assembled 55CM wood stick pendulum?

What is the tip to tip length of a 55CM wood stick pendulum stick?

Exactly what i needed

Just doing my mech to quartz conversion now and came here looking for instructions on how to hook the pendulum onto this drive unit, seems there are none. The hang point is not like the quartz clock module nor my original (which is compatible with the quartz clock but way too heavy). Whilst I will go bend something up, would be nice to have been told how it is supposed to work. With the sales email would have been handy, where the clock instructions also were.

The pendulum hangs onto the hanger that swings back and forth on the external pendulum drive. If the top hook is such it does not hook on snug, it will need to be modified on the customers end to make it hang on there. It does not take much to hang it on, whatever way makes the pendulum attach to it so the swinger can swing it. I will work on the instructions more to make this clear, thank you for the feedback.

James

My pendulum worked about six months with the drive above and then just stopped but shows some effort to move but can’t. Battery replacement didn’t help.

please check the following.

Is the clock level front to back?

Is there anything rubbing anywhere?

Is the bob wacking the sides of the clock case?

Is the pendulum in the unlock position?

Please check these things before we call the movement defective

How does it sound?

No sound made for this pendulum swinger. Does not tell time either.

Most electronic movement have a pendulum swing time lapse too fast. What is the time laps of this pendulum device and is it adjustable ?

Does it make a ticking noise?

No does not

Thank you !

What is the swing range. My pendulum is 35.5” long and has a 4.25” Bob. Thanks ?

I enherited an old grandmother clock which I plan to refit with a quartz battery clock works with chime. The pendulum drive will serve to operate a decorative pendulum. My question : The case has a 9 3/4” interior space width. Will this pendulum drive with a 35.5 long pendulum w/ a 4.25 “ Bob diameter work. I don’t want to bump the inside of the case.

Thanks, Tom

[email protected]

It should be fine.

If it is not, it is possible to dampen the force of the magnete up top that swings it. This is done with duct tape over the magnet so it is not such a strong swing.

James

Thank you !

I am looking replace a mechanical clockworks with a battery powered quartz movement. Could I use this mounted separately to power the pendulum to give it the look of a mechanical works? The old Pendulum is 35.5” long. The Bob is 4.5” in diameter. The interior of the cabinet closet is 9.5” in width. Will your pendulum drive work? Thanks for your reply.

Yes, our Heavy Duty Pendulum Drive will work perfectly for that purpose. If you would like to see our Mechanical to Quartz Kit it is at this link.

https://www.clockworks.com/product/mechanical-to-quartz-floor-clock-conversion-kit

Thank you !

Clockworks Team

James Stoudenmire 30yr Clockmaker Author of Clockworks.com AWI / BHI / Lifetime NAWCC

http://www.clockworks.com 124 Goss Hill = UPS Mailing PO Box 339 = USPS Mailing Huntington, MA 01050 USA clockworks@clockworks.com

Virus-free.

http://www.avg.com

Virus-free.

http://www.avg.com

Yes, our Heavy Duty Pendulum Drive will work perfectly for that purpose. If you would like to see our Mechanical to Quartz Kit it is at this link.

https://www.clockworks.com/product/mechanical-to-quartz-floor-clock-conversion-kit

Thank you !

Clockworks Team

James Stoudenmire 30yr Clockmaker Author of Clockworks.com AWI / BHI / Lifetime NAWCC

http://www.clockworks.com 124 Goss Hill = UPS Mailing PO Box 339 = USPS Mailing Huntington, MA 01050 USA clockworks@clockworks.com

Virus-free.

http://www.avg.com

Virus-free.

http://www.avg.com

I have a mechanical floor clock that has been converted to electric and would be looking to use this product to restore the pendulum function. However, the clock case is narrow. Does this device have adjustments for the amount of swing? I apologize in advance if this is a stupid question (I see you get a lot of those).

The quartz movement post length would depend on the thickness of your clock face.

If you go to the following link, there are several informational tabs that has the directions for measuring, pictures and a chart for reference: https://www.clockworks.com/product/quartz-battery-clock-movement

If you still have questions after reading that please do not hesitate to

No it does not have a swing adjustment – you would have to get a small bob so it will not bonk the sides of the case. The general rule of thumb is to allow 2 inches in each direction for the swing. So if you have a 4 inch bob, you would need a minimum case width of 8 inches to allow for the swing.

Hope this helps!

Is there a way to determine the size of bob to fit in a 16″ wide clock case with a 30″ long pendulum attached to Heavy Duty Pendulum Drive?

Was thinking of using Jauch wood stick pendulum.

Yes it will run it fine.

I was worried that to large a bob might hit the sides of the case. Is there a spec for the angle the Pendulum Drive swings? Or some recommended bob size for my application?

16 inches is pretty wide. The largest pendulum bob diameter is 6.5 inches wide on a wood stick pendulum. The 6.5 wide bob will work fine or anything less is ok also.

Many Thanks !

James and Donna Stoudenmire http://www.clockworks.com 124 Goss Hill = UPS Mailing PO Box 339 = USPS Mailing Huntington, MA 01050 USA clockworks@clockworks.com

Virus-free.

http://www.avg.com

Virus-free.

http://www.avg.com

What size movement I need with you heavy duty pendulum?

What size movement I need with your heavy duty pendulum?

Movement would be separate, so any.

What is the maximum recommended weight for a 40 inch pendulum with this drive

Any weight clock pendulum will work, if the pendulum was made for any clock its good.

I am planning on using items other than commercial pendulums some of which may weigh 3 to 5 pounds. (part of a snow ski, golf club or piece of drift wood) Any thoughts on this application?

No experience with this

How can I add clock mov which size is 2.1×2.1″ wirh this pendulum drive?

Usually pendulum case has a square hole for can add a clock mov.

This is the macro version of that micro version your mentioning.

This one goes on the back of the case and is separate from the movement entirely.

We do not carry the micro version of this any longer sorry