Mechanical Grandfather Clock Weights in a variety of options. Get any part of the weight or the weight complete for your clock, using the weight chart Full article »

Grandfather Clock Weights Description

The Grandfather Clock Weights Description on this web page will cover what is meant by weights and their parts. Any part of the weight is available on its own. We also offer complete weights. If needing a complete clock weight, we need to determine what the appropriate weight is for the clock.

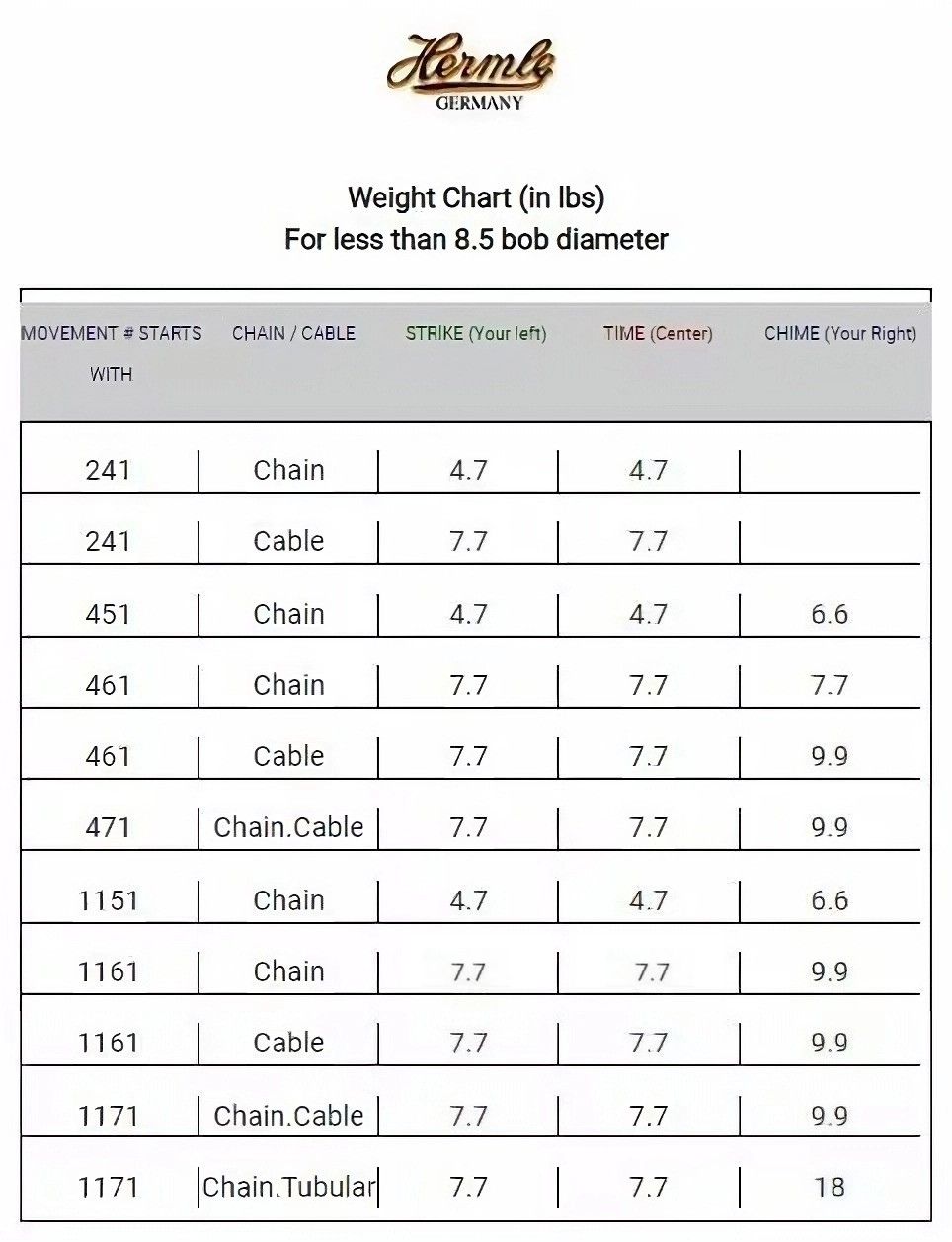

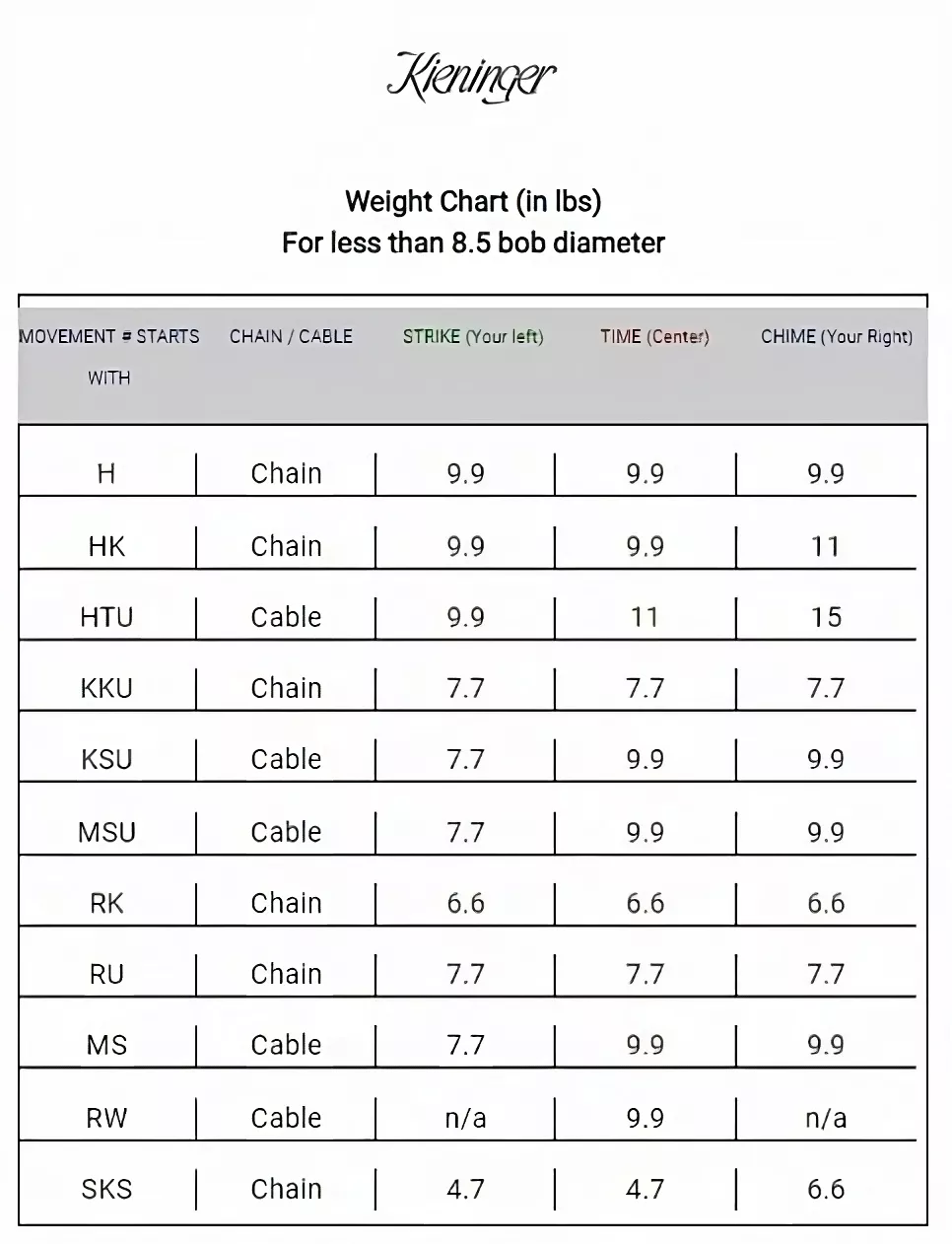

This requires getting the information off of the back plate of the brass movement itself. This information will not be on any of the paperwork or clock case. Once the movement number is known, cross reference that with the weight chart.

The diameter of the bob in another piece of information that needs to be known. The bob is the round disk at the bottom of the pendulum.

The weight chart

Before using the chart, you need to know who made the clock movement. This can be deceiving because the movement can have any name on it, but it may not be the true maker.

For example, a Hermle unit may have the name Sligh, Ridgeway, Howard Miller and so on.

The numbers on the movement is what will lead to getting the correct manufacturer of the movement not the names on the movement. The stamp with these numbers are right on the back plate. Use the movement identification page to find out who made it.

Once the manufacturer is known and the starting numbers of the movement, use the chart to see the weight specifications for the Grandfather clock weights.

Avoiding the weight chart

There is also another way to go about this task, which may be easier. If the movement was made in Germany, post WW2, we can safely make the following assumptions.

If the movement is square and chain driven, it will require [email protected] lbs and [email protected] lbs. These are available in either 47mm or 43mm diameters.

If the pendulum bob is 8 1/2 inches or more, change that rule to [email protected] lbs and [email protected] in 47mm or 43mm. A movement that is rectangle in either chain or cable will use [email protected] and [email protected] LBS in 60mm diameter.

This changes to [email protected] and [email protected] in 60mm diameter if the pendulum bob is 8 1/2 inches or wider. These specifications do not apply if the clock has 5 or 9 big tubes on the back. Also this rule is not for all Grandfather clock weights but the vast majority of the post WW2 German units.

Close enough is good enough

The weight specs list it as 4.7 or 6.6, however this is really being too picky. If getting it close to those numbers that is fine. In fact if ordering a 4.7 lb weight, it may come 5.3 or whatever, but that is just fine.

There has to be some sort of reference for the factory to label the Grandfather clock weights so it is what it is. Just know if it is a pound over that is fine. If it's a little under, that is fine also. They do not have to be exact.

Often wrong from the start

In fact, there is a lot of clocks in the world sold new with the wrong Clock Weights on them from the start.

Clockworks will do a repair and they will say the clock ran for 30 years straight and come to find out they had Grandfather clock weights that were a pound or two too heavy. If the weights are a little too heavy it is fine. A lighter weight may or may not be fine because it may not trigger the movement to work properly.

Grandfather Clock Weights Description - Conclusion

Grandfather clock Weights are not cheap mainly because they are so heavy to keep, ship, store, move from here to there.

Sure one weight set of three is less than 30 lbs but that adds up quickly in a stack of weight sets.

With that said, we don't want to ship these back and forth. It is best to get the right weights the first time. To return these is not an inexpensive or easy task. For example, suppose we charge $30 to ship these and for some reason they are wrong. Then it is $30 to get them back to us and another $30 to send out a new set.

In addition, UPS charges a fee to send a call tag for them to come back. That is $110 to UPS for no reason. So if there are questions, please ask.

Grandfather Clock Weights Stuck

The Grandfather clock weights can get stuck in the high position if over wound. Some larger clocks have over wind protection to prevent this.

The grandmother and grandfather chain drive units often do not have this feature. When winding the weights up make sure the top of the weight can be seen when done. Never go to the point where the top of the shiny weight cover can't be seen.

Chime weight stuck

The chime weight is on the right as you face the clock and has the heaviest weight. Using cloth gloves, or at least a cloth of some kind, pull down on the weight some.

This is the same as making the weight weigh more. At the same time, turn the minute hand past the quarter hour to see if it will engage the chime. When you advance the time and make it chime, the weight will slowly come down. This will hopefully be enough to activate and run the chime on its own.

Time weight stuck

The time weight is the center weight which can be light or heavy depending on bob size.

This is the hardest weight to deal with out of the three. Try pulling down some while swinging the pendulum.

See if it starts running on its own when letting go. If this does not work, take off the pendulum. All it will have is the pendulum leader hanging on the back of the movement.

This will make it tick tock faster than if the pendulum was on. The leader will tick tock faster as you pull down some on the weight. The weight will then come down enough to run the clock.

If all else fails, and it’s a chain driven clock, you would need to cut the chain in half, or break a link, to take the movement out of the clock. With the movement out of the clock you can fix it.

Strike weight stuck

The strike weight is on the left as you face the clock and has the lightest weight. Only after the chime weight is operating correctly can you work on the strike weight.

If the clock does not run through the chime sequence it will not get to where it strikes out the hours. With some cloth gloves on, or at least a cloth of some kind, pull down on the weight some.

Again, this is the same as making the weight weigh more. Doing this will make the clock strike. Advance the minute hand and let it chime each quarter until it plays the top of the hour song. Then pull a little on the weight when it is going to strike out the hours.

Keep advancing the time with the minute hand, as to make it chime and strike. Then slowly the weight will come down enough to be able to activate and run the strike on its own.

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception) If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception) If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)Changing a Clock Cable

Changing a clock cable requires the movement to be out of the clock case. These instructions refer to post WW2 modern grandfather units of German origin, however all makes have a similar method. Swapping the cable is easy. There is a big hole and a little hole on the cable mount.

The cable end fits into the big hole, then slides over to seat into the little hole. When the lock is set, it seats in securely. It's the same basic theme on both ends of the cable, meaning, one slot being in the cable drum itself and the other on the movement.

The cable drum side of the cable

To remove, lift the cable up from the oblong hole on the drum and slide it over to the big side. The cables have ends made of brass on them. These get slid over from the small side of the slot on the cable drum to the larger slot. It will release so as to remove it from the clock movement.

The other end of the cable

The movement itself would normally have the plates set for the cable ends. The cables have round brass ends on them and these lock into a plate on the movement.

This plate will have a small hole leading to a big hole. To remove the cable it requires only lifting the end and moving over to the big hole and out.

Mechanical Clock Weight Pulley

Solid brass cable pulley for Hermle / Urgos / Kieninger mechanical clock movements. Available in two sizes 1 3/4 inch diameter or 1 1/4 inch diameter. The grandfather and grandmother clock series will take the 1 3/4 wide pulley. Wall clocks of German origin will take the 1 1/4 inch diameter.

Do grandfather clocks occasionally need to have the cable(s) replaced?

Yes after many years it is best to check for frayed cable evidence and consider replacing

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

what is the best way to prepare a clock for shipment?

Sending A Clock for Repair

Sending A Clock for Repair is easy because we here at clockworks.com need the movement alone. We get clock repairs shipped to us from all over USA and Canada. There is never a problem doing this as long as the movements are double boxed and well protected. Here are some guidelines on how to ship the movement and also what to expect.

Packing The Movement

Undoubtedly, the safest way to pack the movement is to box it up nice and tight with the hand shaft facing up. This is very important! Make sure the movement cannot bounce around inside the box. The next step is to pack that box inside another box. If sending it like this, there will be no problem getting it to us. It does not even have to be put together. Sending us a bag of parts and the movement plates is ok also. It does not matter as long as it’s all there. Don’t laugh, we have had this happen many times! We know how to put it back together, so don’t worry.

Protect the clock hand shaft

When packing up the movement, take special care to protect the hand shaft as this is hard to correct if it gets bent. This is the shaft that the hands go on to tell the time. Pack the movement up well with newspaper and bubble wrap. If using packing peanuts make sure to put the movement inside a plastic bag first! Please do not let the movement get peanuts all up inside of it.

Again, when placing the movement inside the box make sure to place it in with the hand shaft pointing up. Once the movement is packed really well in a box, pack it again in another box with more packing material. The movement should not be able to bounce around inside the first box. Double boxing provides extra cushion for the movement as it travels to minimize the possibility of damage.

What not to ship us

We only need the movement itself. Do not ship us the dial, weights, pendulum, chime block or any other part that is not the clock movement itself. There is no point in sending back and forth parts that we do not need, to risk damage. The dial and pendulum get easily damaged when shipped, unlike the movement that ships well.

Sending the movement for repair by UPS

If you have a UPS account, or have access to ship it via UPS, just send it along after filling out the form. If it is a problem getting it shipped out, let us know the weight and dimensions of the box and we can email a UPS label for a low price. Shipping centers are unreasonably expensive when it comes to packing and shipping something. If boxing it up as described and ship it to us with the label provided, it will be substantially less cost than a place like Mailboxes, etc to pack and ship. Please email us at clockworks@clockworks.com with the weight and dimensions of the box if this sounds better. Of course, there is the option of go priority mail as well.

After the movement is packed up, please send it to: CLOCKWORKS 124 Goss Hill Rd, PO Box 339, Huntington, MA 01050. If the following form is filled out, we will get notification that the clock is coming. You will receive an email confirmation of the form submission.

Clockworks

PO Box 339

124 Goss Hill Rd

Huntington MA 01050

800-381-7458

clockworks@clockworks.com

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Perfect find.

Thank you, glad it worked out

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Very excited for this!

Where can I find a connector between pendulum guide and the crutch. I’m having difficulties locating that piece or is it part of the

What are the movement numbers off of the back plate of the movement itself?

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

have a Ridgeway grandfather clock. one small screw i the roller/pulley system broke nd dropped the weight to the ground. How do I get a replacement screw?

Best to get the pulley from this link

https://www.clockworks.com/product/mechanical-clock-weight-pulley-copy

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

The pin in the clock weight pulley broke. How do remove that pin or if I get this new part is that pin screw in to itself??

Hi

Do not have the pin but we have the pulleys no problem

See pulleys = https://www.clockworks.com/?post_type=product&s=Pulley

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com