Mechanical Grandfather Clock Weights in a variety of options. Get any part of the weight or the weight complete for your clock, using the weight chart Full article »

Grandfather Clock Weights Description

The Grandfather Clock Weights Description on this web page will cover what is meant by weights and their parts. Any part of the weight is available on its own. We also offer complete weights. If needing a complete clock weight, we need to determine what the appropriate weight is for the clock.

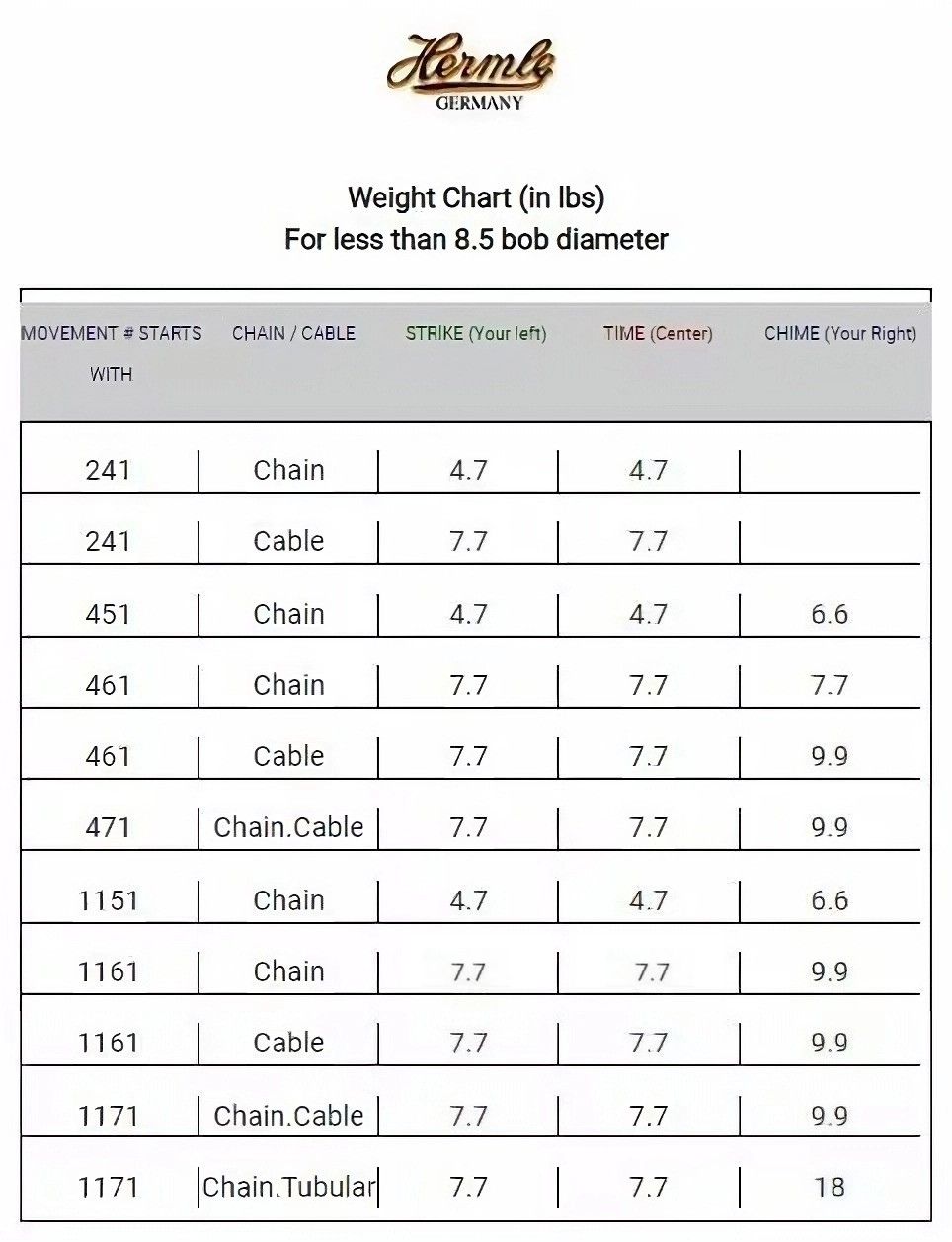

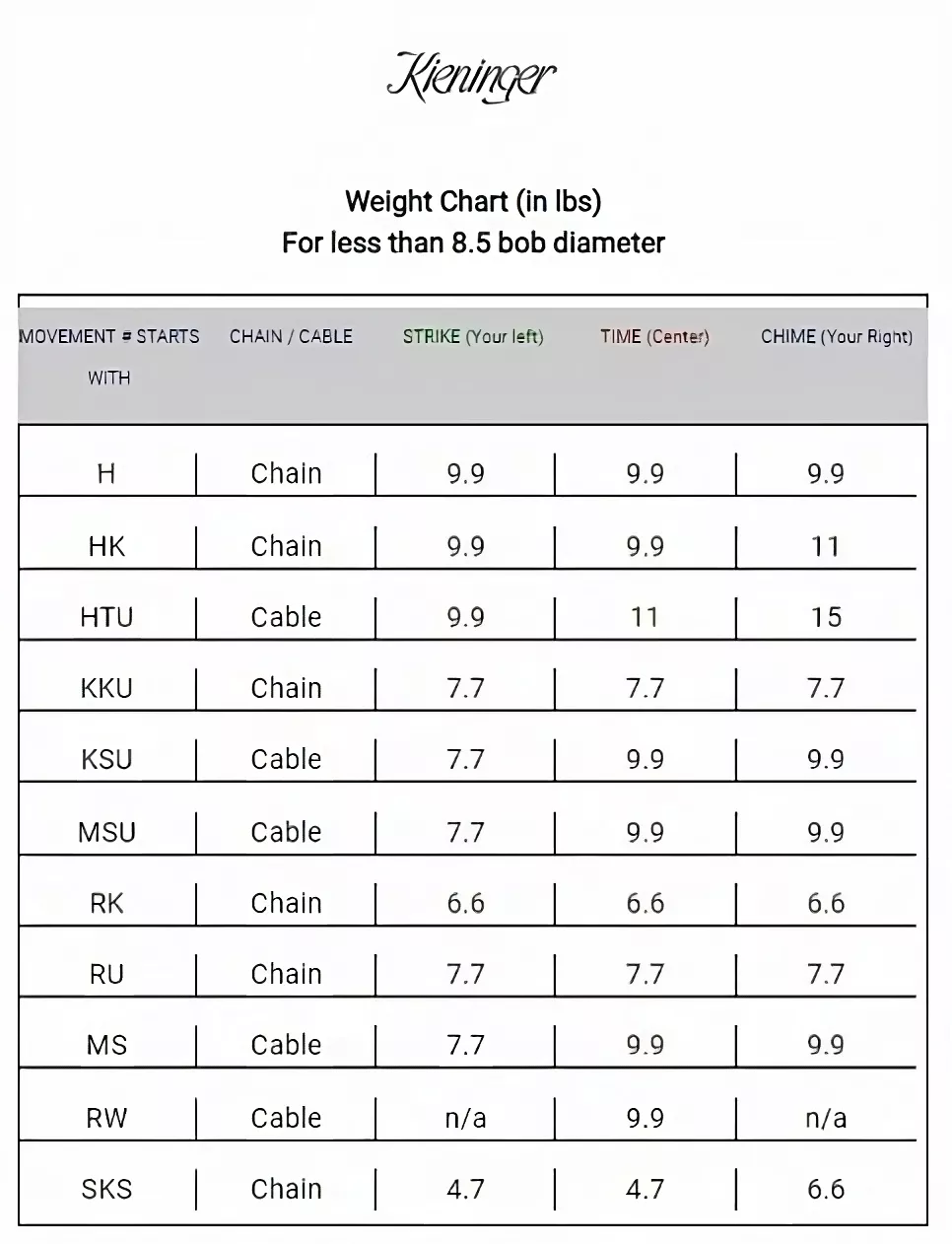

This requires getting the information off of the back plate of the brass movement itself. This information will not be on any of the paperwork or clock case. Once the movement number is known, cross reference that with the weight chart.

The diameter of the bob in another piece of information that needs to be known. The bob is the round disk at the bottom of the pendulum.

The weight chart

Before using the chart, you need to know who made the clock movement. This can be deceiving because the movement can have any name on it, but it may not be the true maker.

For example, a Hermle unit may have the name Sligh, Ridgeway, Howard Miller and so on.

The numbers on the movement is what will lead to getting the correct manufacturer of the movement not the names on the movement. The stamp with these numbers are right on the back plate. Use the movement identification page to find out who made it.

Once the manufacturer is known and the starting numbers of the movement, use the chart to see the weight specifications for the Grandfather clock weights.

Avoiding the weight chart

There is also another way to go about this task, which may be easier. If the movement was made in Germany, post WW2, we can safely make the following assumptions.

If the movement is square and chain driven, it will require [email protected] lbs and [email protected] lbs. These are available in either 47mm or 43mm diameters.

If the pendulum bob is 8 1/2 inches or more, change that rule to [email protected] lbs and [email protected] in 47mm or 43mm. A movement that is rectangle in either chain or cable will use [email protected] and [email protected] LBS in 60mm diameter.

This changes to [email protected] and [email protected] in 60mm diameter if the pendulum bob is 8 1/2 inches or wider. These specifications do not apply if the clock has 5 or 9 big tubes on the back. Also this rule is not for all Grandfather clock weights but the vast majority of the post WW2 German units.

Close enough is good enough

The weight specs list it as 4.7 or 6.6, however this is really being too picky. If getting it close to those numbers that is fine. In fact if ordering a 4.7 lb weight, it may come 5.3 or whatever, but that is just fine.

There has to be some sort of reference for the factory to label the Grandfather clock weights so it is what it is. Just know if it is a pound over that is fine. If it's a little under, that is fine also. They do not have to be exact.

Often wrong from the start

In fact, there is a lot of clocks in the world sold new with the wrong Clock Weights on them from the start.

Clockworks will do a repair and they will say the clock ran for 30 years straight and come to find out they had Grandfather clock weights that were a pound or two too heavy. If the weights are a little too heavy it is fine. A lighter weight may or may not be fine because it may not trigger the movement to work properly.

Grandfather Clock Weights Description - Conclusion

Grandfather clock Weights are not cheap mainly because they are so heavy to keep, ship, store, move from here to there.

Sure one weight set of three is less than 30 lbs but that adds up quickly in a stack of weight sets.

With that said, we don't want to ship these back and forth. It is best to get the right weights the first time. To return these is not an inexpensive or easy task. For example, suppose we charge $30 to ship these and for some reason they are wrong. Then it is $30 to get them back to us and another $30 to send out a new set.

In addition, UPS charges a fee to send a call tag for them to come back. That is $110 to UPS for no reason. So if there are questions, please ask.

Grandfather Clock Weights Stuck

The Grandfather clock weights can get stuck in the high position if over wound. Some larger clocks have over wind protection to prevent this.

The grandmother and grandfather chain drive units often do not have this feature. When winding the weights up make sure the top of the weight can be seen when done. Never go to the point where the top of the shiny weight cover can't be seen.

Chime weight stuck

The chime weight is on the right as you face the clock and has the heaviest weight. Using cloth gloves, or at least a cloth of some kind, pull down on the weight some.

This is the same as making the weight weigh more. At the same time, turn the minute hand past the quarter hour to see if it will engage the chime. When you advance the time and make it chime, the weight will slowly come down. This will hopefully be enough to activate and run the chime on its own.

Time weight stuck

The time weight is the center weight which can be light or heavy depending on bob size.

This is the hardest weight to deal with out of the three. Try pulling down some while swinging the pendulum.

See if it starts running on its own when letting go. If this does not work, take off the pendulum. All it will have is the pendulum leader hanging on the back of the movement.

This will make it tick tock faster than if the pendulum was on. The leader will tick tock faster as you pull down some on the weight. The weight will then come down enough to run the clock.

If all else fails, and it’s a chain driven clock, you would need to cut the chain in half, or break a link, to take the movement out of the clock. With the movement out of the clock you can fix it.

Strike weight stuck

The strike weight is on the left as you face the clock and has the lightest weight. Only after the chime weight is operating correctly can you work on the strike weight.

If the clock does not run through the chime sequence it will not get to where it strikes out the hours. With some cloth gloves on, or at least a cloth of some kind, pull down on the weight some.

Again, this is the same as making the weight weigh more. Doing this will make the clock strike. Advance the minute hand and let it chime each quarter until it plays the top of the hour song. Then pull a little on the weight when it is going to strike out the hours.

Keep advancing the time with the minute hand, as to make it chime and strike. Then slowly the weight will come down enough to be able to activate and run the strike on its own.

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception) If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception) If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)

If the pendulum bob is 8.5, or larger, the time weight should be the same as the chime weight instead. (Tubular Bell movements are an exception)Changing a Clock Cable

Changing a clock cable requires the movement to be out of the clock case. These instructions refer to post WW2 modern grandfather units of German origin, however all makes have a similar method. Swapping the cable is easy. There is a big hole and a little hole on the cable mount.

The cable end fits into the big hole, then slides over to seat into the little hole. When the lock is set, it seats in securely. It's the same basic theme on both ends of the cable, meaning, one slot being in the cable drum itself and the other on the movement.

The cable drum side of the cable

To remove, lift the cable up from the oblong hole on the drum and slide it over to the big side. The cables have ends made of brass on them. These get slid over from the small side of the slot on the cable drum to the larger slot. It will release so as to remove it from the clock movement.

The other end of the cable

The movement itself would normally have the plates set for the cable ends. The cables have round brass ends on them and these lock into a plate on the movement.

This plate will have a small hole leading to a big hole. To remove the cable it requires only lifting the end and moving over to the big hole and out.

Mechanical Clock Replacement Cable

Mechanical clock cable for cable driven clock movements. You must knot the ends on this cable as they do not have the fittings already on them.

This clock cable is .040 (1.0mm) thick and is the most common thickness for post 1950 cable driven floor clocks. In addition, there are various lengths to choose from in the drop down menu.

Hello. I have a Sligh Grandfather Clock with movement number: 2061-853 SK 114cm. Which cables do I order. Also, how many feet should I purchase?

Thank you

This link

https://www.clockworks.com/product/genuine-replacement-cable-for-grandfather-clocks

For a 1161, will work just the same

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a Sligh grandfather clock/ we moved to a different house and have lost the cables! Ugh

Model #825-1-AB

Movement #500-0004

Purchased 12/1994

Where do I search to purchase new ones ?

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

K 10. 100 cm

I have Howard miller grandfather clock need a center weight cable clock numbers 2224219909 musol 116cm 354394

This link

https://www.clockworks.com/product/genuine-replacement-cable-for-grandfather-clocks

Get the one that says K or MS series

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hello, I have a beautiful Howard Miller Floor Grandfather Clock which we purchased in 1989. It has 3 heavy weights and I inadvertently cut one of the six cables when packing it for moving. This really upset me since I’ve babied this clock and taken good care of it always. Is there a way that I can replace the cable easily ? I’ve read some of your info on changing out the cable but it’s still fuzzy to me. Can you help? Thank you for your consideration. Judy

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Is this any help? MODEL 610-440

MOV’T 354181I

DIAL 270324I

WGT 390534I

PEND 280108I

SER # 91400148

I couldn’t find any other numbers but it’s kind of awkward so if you want me to search further, I’ll try. Thank you.

Need from the brass plate on the movement

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have tried everything to get a pic of the back of the movement, but I haven’t had any luck at all.

Is there any other way to identify what I need to fix or replace the cable?

Thank you for your consideration.

I emailed a pic to you but it’s a non-reply email. Can you give me a real email address?

clockworks@clockworks.com

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

If you provide a pic of the clock dial I can tell what movement it is maybe

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

My computer has been down for a couple days. I will try to email a photo to you. Judy

I would like to get a copy of the clock face to you so you might be able to identify my Howard Miller floor clock.

I wasn’t able to get a pic of the model/serial number so you suggested a pic.

I cannot copy the pic to your website. Can you provide me with an email address so I can get it to you?

Thank you for your help, Judy

The email address is clockworks@clockworks.com

I look forward to seeing the pics

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a Seth Thomas Regulator #2, 5881C.

The movement moves freely, but is missing the weight assembly.

Do you have the necessary parts?

Hi,

Whatever it is it is required in parts for that clock movement is no longer made or available.

Something custom would be made or modification to that what does exist. Or we would need to match it up to one of our own parts units.

If you would like to send it in for restoration, we could figure it all out here, along with the restoration process.

Are you interested in sending the movement only?

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

This is great stuff.

Thank you, glad it worked out

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com