Clock pendulum components description

Altogether, this is a description of the clock pendulum parts and components. Please use this as a glossary for parts in a clock pendulum assembly.

Knowing the correct terms for the various pendulum parts is helpful when ordering replacements. We are quite adept at deciphering descriptions of parts however, knowing the name is always something we welcome.

The clock pendulum

First, a clock pendulum includes the bottom rating nut and threads, the pendulum bob, and top hook.

Additionally, these items are removable on wood stick pendulums only. Lyre metal clock pendulums do not have the ability to come apart.

Clock pendulum leader

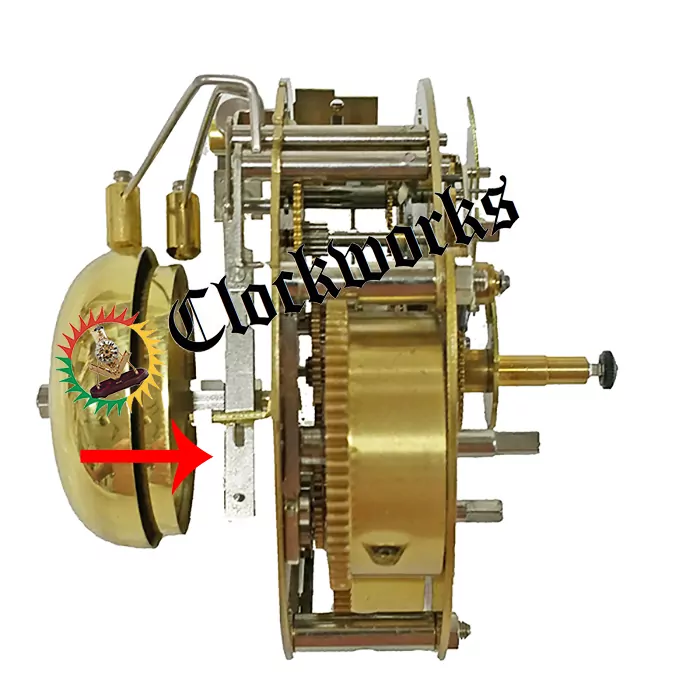

Second, a leader is the part that the pendulum hangs onto when it is on the clock. It then in turn hooks to the suspension spring on the very top of the pendulum assembly.

Naturally, pendulum leaders vary depending on the manufacturer of the clock movement and they can also vary in length, as well as style. Sometimes there can be more than one type of leader for the same movement.

There are also instances where we custom make leaders for customers.

Suspension spring description

The clock pendulum suspension spring is the short spring steel part on the very top of the pendulum assembly. Its purpose is to suspend the leader and pendulum in the air. Generally speaking, its steel, spring like strips, flex to let the pendulum swing back and forth with ease and momentum.

Clock Pendulum Components Complete

In summary, the clock pendulum components include the pendulum hanging on the leader and the leader hanging on the suspension spring.

Put the complete pendulum assembly on the clock and it is ready to go. The next step is to put the clock in beat and run the clock to see how the time keeping is.

Replacing Lost Pendulum Parts

By and large, replacing a lost pendulum part from its assembly is a process. It is more in depth than just matching up the broken pendulum part.

Certainly, narrowing it down requires a different method than just observation. The following text will guide you through that process.

The lost pendulum

First, identify the movement manufacturer. This is the beginning step to identify a lost clock pendulum. This is done by getting the movement numbers off of the back plate of the movement itself.

That is to say, it will not be in the manual that came with the clock. Moreover it will also not be on any stickers or the clock case.

Match the movement number here to find out who made the movement. Finally, proceed to the pendulum page. This is the first step in replacing a lost pendulum as well as replacing lost pendulum parts.

Lost pendulum leader

The leader hooks to the suspension spring. The suspension spring is at the top of the movement. The pendulum hangs onto the leader.

All, or some, of these parts are what you need to order to replace lost pendulum parts. Again, the order of the parts is the suspension spring, the leader, then the pendulum.

If the leader is missing, identify who made the movement. Use the above information to correctly identify the movement so it is possible to replace the pendulum part.

When you know who made the movement, it is easy to narrow down the possibility of what leader you need. This makes things much easier when replacing lost pendulum parts.

After knowing the manufacturer, match the information to a leader shown on this page.

In the final analysis, visually inspect the pendulum hook style, the crutch on the back of the movement, and the suspension hook.

Finally, compare the components of the clock to the options in that manufacturer category to figure out the best one. Replacing lost pendulum part can be tricky however with these descriptions the task should be less daunting.

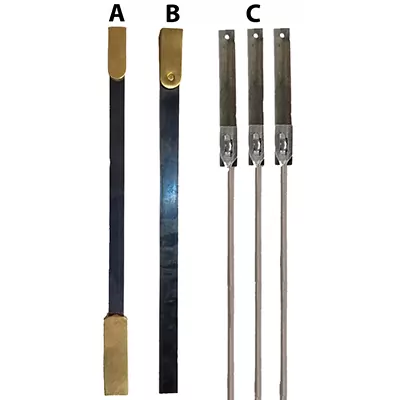

The lost suspension spring

First know that style A is the very most common suspension spring style in existence. Check the top of the pendulum leader and if there is a double hook on the end it will be style A required for the clock.

Generally speaking, use style A3 for large grandfather units, A2 for grandmother and wall clocks, and A1 for mantle clocks. Suspension spring are one of the easier parts to ascertain when replacing lost pendulum parts.

The mechanical clock pendulum length

A pendulum clock without a pendulum is a shame for sure. Hence, getting the mechanical clock pendulum length correct does take some diving into the clock world.

If there is no idea what pendulum it would take, this is a basic guide. Of course, this is a basic guide to narrow it down to the best pendulum for the clock. This will cover most situations, without special equipment to figure out the length.

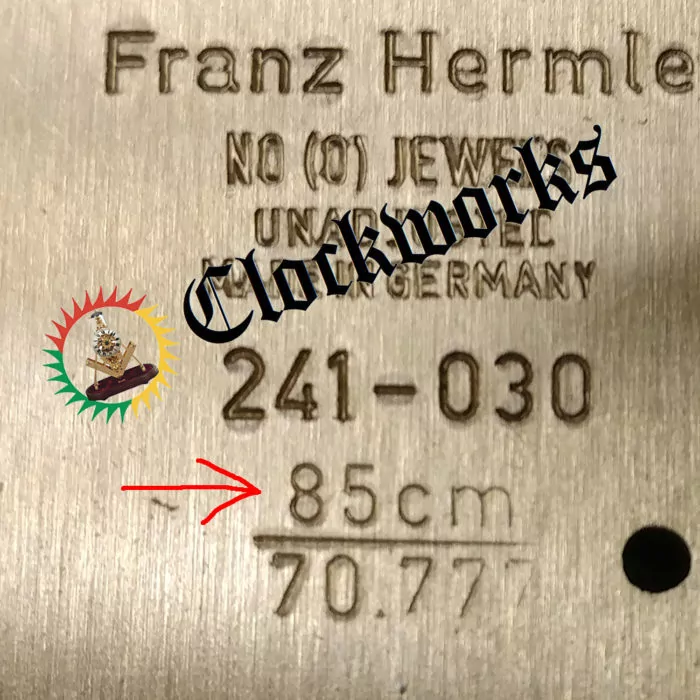

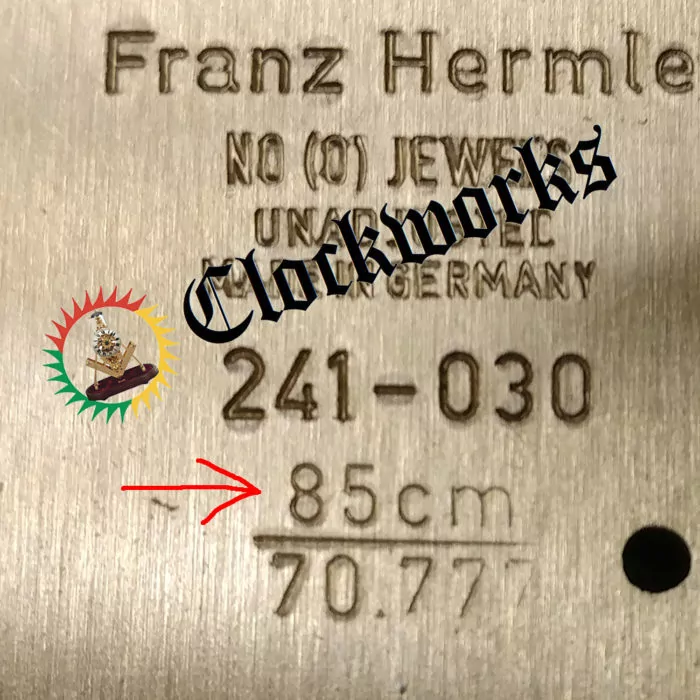

The movement CM or PL stamp

On the back plate of the clock movement usually, there are some numbers and or letters for identification. Likewise, there may be an indication of how long the pendulum should be in the mix of these numbers.

It may say CM or PL and this stands for centimeter or pendulum length. Subsequently, this would be the length where it should keep approximate time. Generally, there are a few different ways to measure this depending on the country of origin.

Mechanical Clock Pendulum Length for German made movements

Most mechanical German made clock movements are easy to figure out the pendulum length. In essence, the numbers will let us know or the stamp will clearly state the CM or PL number. If it is German, keep in mind the CM length is not the actual pendulum length.

Altogether, German units measure this length from the top of the clock movement, and this includes the three components of the pendulum all in one length, in centimeters.

This length will include the pendulum itself, the leader that it hooks to, and the suspension spring on the top that the leader hooks on to, all in one CM measurement. To clarify, CM stands for centimeter and PL stands for pendulum length.

If no stamp try to convert

When there is no stamp with the CM on the movement, there are some additional steps that need to happen. You will need to cross reference The numbers on the back plate to the pendulum length that you need. The first step is to identify the manufacturer of the clock movement by using the movement numbers.

The movement numbers indicate who the actually manufacturer is of the movement. Various clock retailers may have a stamp of their name on it, but the numbers are always true to the manufacturer.

Converting numbers to CM length

Moreover, some movements do not have an indication of the pendulum length on the back plate. The unit will have a number that would need to be found on this website first to find out what the correct CM length is for it.

Conversion number example

Generally speaking, let's say that the movement has no CM stamp on the movement and only shows the Urgos number UW32319.

Go to the identification page to look at the movement number examples. In this example, we see that it is a Urgos. Now it is possible to go to the Urgos page and find the number to see what the pendulum length is.

In this example, the pendulum length would be 80cm, representing the full length with the size including the size of the bob.

German grandfather movements

Almost all grandfather clock movements are going to be German if made after 1950. The first thing we need to do is get the numbers off of the back plate of the movement. This is the only way, and we can't cheat by looking at the paperwork or clock case.

It has to come right off the back of the clockworks. The manual and the sticker on the case is of no use to get the pendulum.

American clocks

The American mechanical clock movement manufacturers refer to the pendulum length as a "drop". The drop is the length of the pendulum from the hand shaft all the way down to the bottom of the pendulum rating nut threads.

It is a different way of measuring the pendulum length then the German made way. The basis for both ways are on the smallest bob diameter. If the bob is larger or heavier, the length would be longer than what the stamp indicates.

No luck

If everything fails for one reason or another, the best chance for a pendulum is the wood stick style. This is the only style of pendulum that can be easily modified because it can be cut down.

These types of clocks are usually antiques, or of Asian origin, and information such as pendulum length is simply not available. Sometimes it takes a good guess on where the manufacturer meant to have the bob sit. To do it this way, you only need a pendulum with a stick that is way too long to begin with.

Chop it, try it, chop it, try it. Each time slowly cut an inch and half off of the sticks length and hang it back on. It will only take a couple of times, and if starting way too long it can always go shorter.

Clock makers method for Mechanical Clock Pendulum Lengths

There is another way, which is known as setting the beat rate. This is a more complex way and is usually just done by clock makers. It involves a beat detecting device that counts out the beats per hour, or the beats per minute. To do this, first figure out what the beat rate is suppose to be for that particular movement.

Then keep adjusting the pendulum length until it keeps time. There are cell phone apps out there these days that will tell the beat rate and the cell phone will listen and say if the clock will keep time with that pendulum. Go longer or shorter until the phone says the beat rate is set.

Contacting us for help with Mechanical Clock Pendulum Lengths

Please email the movement numbers from the back plate, and explain what part you need. The email address to send this information to is [email protected]. We always welcome pictures but they are not a necessity. If emailing pictures please include the back side of the clock movement where the markings are.

Timing a mechanical pendulum clock

Timing a mechanical pendulum clock is all about the overall pendulum length. Rarely has anything to do with the movement itself, unless the movement not geared to the proper length from the start.

A mechanical clock is easy to time providing the correct pendulum. When the pendulum is correct for that particular movement it will hang on the leader and keep approximate time.

The fine timing can be done only with the pendulum adjustment located at the very bottom. At the bottom of the bob is some adjustment threads and a nut.

To turn the nut one way raises the bob and the other lowers it. A shorter pendulum will make the clock run faster. A longer pendulum makes the clock run slower.

Fine timing the clock

If the clock is timing slow, raise the pendulum bob by turning the nut at the bottom of the bob. If the clock is fast, do the same but lower the clock's pendulum bob instead. One full turn is somewhere around 1-2 minutes a day faster or slower.

If there is no more adjustment

If the bob is all the way up and its still too slow or fast, shorten either the pendulum or the leader it hangs on to correct.A lyre pendulum that does not keep time with the bob all the way adjusted will need its length altered. It can be altered with the overall length by the pendulum itself or the leader it hangs onto.

The leader is about 5 to 7 inches long and engages with the crutch on back of the movement. The leader is the part that the pendulum top hook will mount to.

It is possible to shorten or lengthen the pendulum leader to put the clock in time range with some solder if needed. 1 3/4 inches is a good measurement to make one of these longer or shorter as needed, as this is the length of the threads at the bottom of the bob.

So it will give a full timing adjustment range all over again and can go up or down as needed.

German pendulum length CM stamp

The pendulum length is overall and not just the pendulum itself. These German units measure there pendulum lengths from the top of the movement and all the way down. This will include the suspension spring, the leader and also the pendulum itself.

This is based on a 4 1/2 inch bob diameter. Of course the larger the bob, the longer it will be beyond that CM stamp measurement.

Used to keep time, now does not

If the clock kept time in the past but now does not, it means a worn gear. The escape wheel is worn and it is advancing more than one tooth at a time.

The escape wheel alone would be hard to find, and hard to replace both. The entire movement would be disassembled to replace this worn escape wheel if there is another one found that will work.

The cost of having this done would be the same price as a new movement. There is no such thing as having a repair on a clock movement being better than a new movement.

The price would be about the same for a complete overhaul or a brand new one. First see if the clock movement is in production and available new. We do this by getting the numbers off of the back plate of the movement itself, right off of the brass. Please email and we will check the availability and quote for the new one.

If the movement is not in production anymore, then a movement restoration is the only option. You can ship the movement to Clockworks Attn Repair department for a beautiful restoration.

Mechanical Pendulum Clock Timing Issues - Conclusion

Fine timing of the clock is easy as seen. If the clock kept time in the past and now too fast, its time for a new movement and has nothing to do with the pendulum. A worn escape wheel is most likely the cause and a new unit would be less cost then a repair.

Clock Pendulum Suspension-Spring Information

The following is a discussion on clock pendulum suspension-spring information. Naturally, suspension springs do not have to be exact in length. If the clock runs slow, simply raise the pendulum bob with the rating nut at the bottom.

Likewise, if the clock is running fast then turn the rating nut to lower the pendulum bob.

Most common springs

By and large, suspension spring A is the most common style suspension spring. Of course, it is most likely the one by default.

If the old suspension spring looks similar to this one then it is right. As a general rule of thumb, small mantle clocks take suspension A1, wall clocks and small grandmother units will take suspension A2.

The A3 size is for grandfather clock units with a larger pendulum bob diameter.

This size can also be seen on Grandmother clocks with larger bob diameters. Use the larger A3 with large bob diameters so the bob will not wobble front to back.

If using a pendulum with a bob of 8 1/2 inch diameter or larger please order Suspension A3 for this reason.

Not as common

Urgos uses the single hook style as seen in picture suspension B. However suspension A was the very most common to use.

Very old antique round movements mainly use Suspension C and Suspension D. These are mainly French clocks and US made units made prior to 1945.

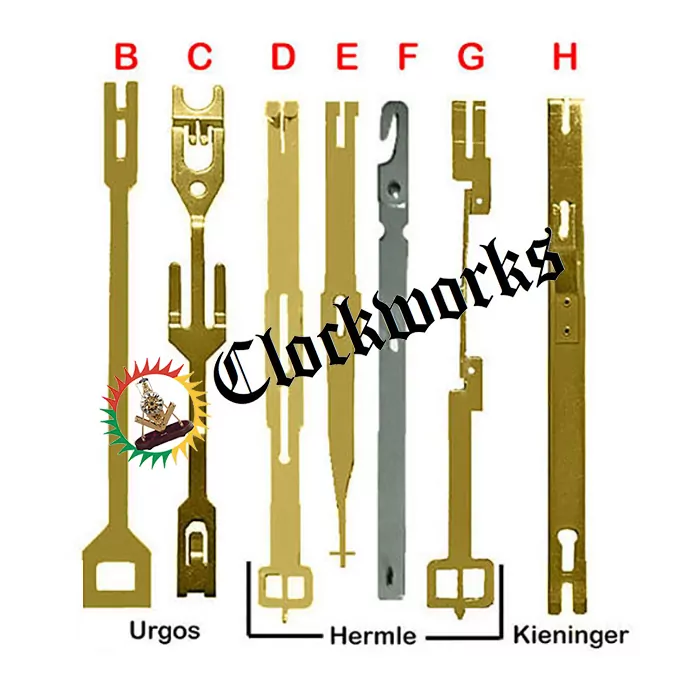

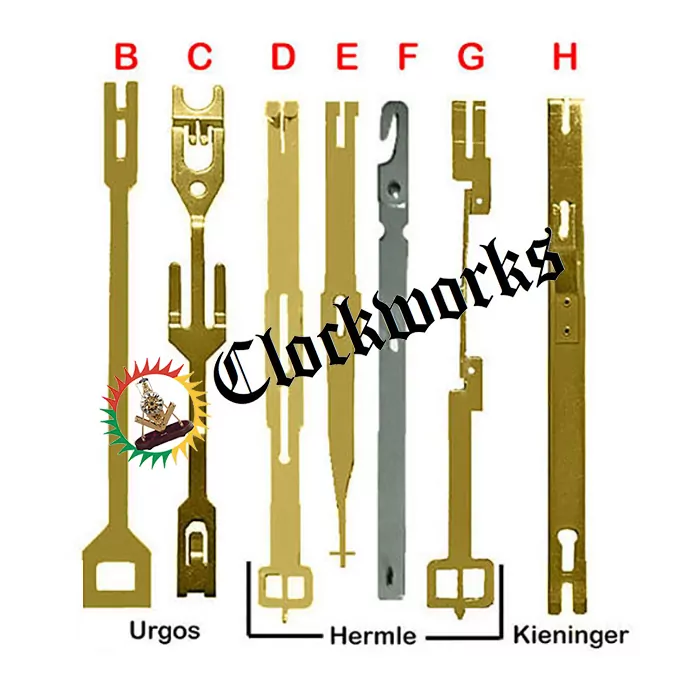

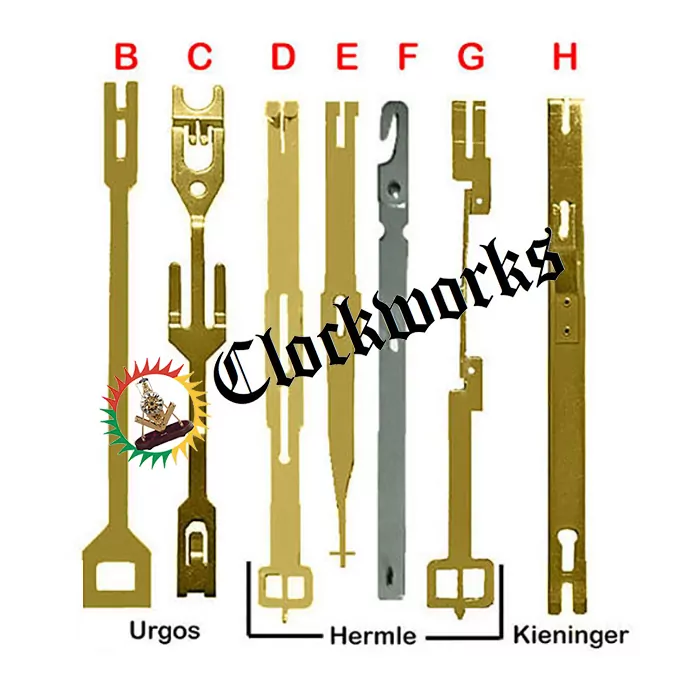

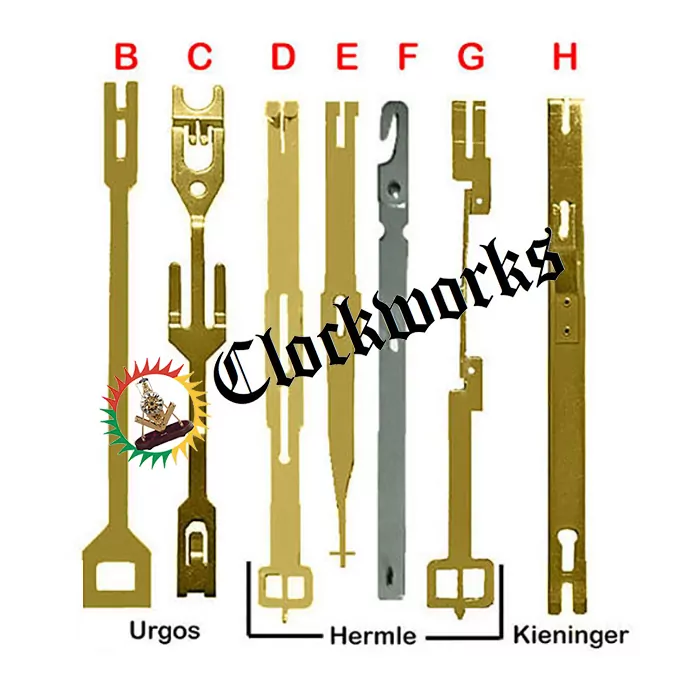

Clock Pendulum Leaders

Mechanical pendulum clock leaders for post 1950 movements. These leader will fit clock movements made in Germany after WW2.

The first step to replace a lost leader is to visually match one to the old leader.

If the leader does not match up to any of the ones listed, please email us. A picture is always helpful. Look to see if the leader needs a double hook or a hole top in order for it to mount to the suspension spring. Similarly, check the other end and notice that configuration as well.

What is the required mount style for the pendulum to hang on the clock? In the middle section, what one will engage with the swinging crutch on the back of the movement? These are all important factors to consider when replacing the leader.

The length of the leader

If the leader is missing, however, there are some more steps to figure out what the leader length should be. Not all leaders have variable lengths and the ones that do are for Hermle and Kieninger clock movements only.

Kieninger is easy. Those leaders only come in two lengths. Grandfather clocks by Kieninger take the 7 inch leader. Wall and mantle units take the shorter leader.

Hermle leaders are much more in depth. Determining which leader is the correct length for a Hermle is a process. The next section will describe the ones available.

Hermle leader lengths

A Hermle floor or wall clock will always take leader D or G. leader E is for a low bridge to a high bridge conversion on a Hermle grandmother clock. Therefore, the elimination of this from the list of choices is viable if a conversion is not being done.

The next choice is leader F which is for mantle clocks. This one is also for creating custom pendulum lengths. Additionally, leader F and leader G are interchangeable.

So if you need leader G, a leader F can take its place with an alternate length. Please email us with any questions about Hermle leaders.

Leader F for Hermle mantle

Usually mantle clocks with a Hermle clock movement will take leader F. In a situation where the leader is missing and the length is unknown, the following steps need to be taken.

This will ensure that the correct leader length is chosen. First, use the CM number off of the back of the movement. This CM length is the pendulum length from the top of the movement all the way down to the bottom of the pendulum.

It is not the length of the pendulum itself. Often times this measurement can be confusing. It is important to measure this correctly. Failure to do so will result in the clock not keeping proper time.

Second step, is to take this CM length and divide it by 2.54 to get the inch equivalent. Then subtract the length of the pendulum and the suspension spring length from this measurement. The measurement that is left is the length you need for leader F.

There are 1 1/2 inches of thread at the bottom of the pendulum for fine adjustment. Because there is so much room for adjustment, this measurement does not have to be exact. If there wasn't any extra length then it would need to be more precise. However this is not the case so close is good enough.

If the leader is the wrong length

Determine the timing of a clock by the length of the pendulum and the weight of the pendulum bob. This can get a bit confusing for some people. There is a stamp of the overall pendulum length on the back plate of the clock movement with a CM number.

This CM stamp is the overall pendulum length from the top of the clock movement all the way down to the bottom of the rating nut. The basis for this is on the smallest bob diameter.

Subsequently, a wider pendulum bob will require a longer pendulum. Again, this can get a bit tricky. Please feel free to send an email with any questions. We will be glad to help.

Often enough a clock will either run too fast or too slow. If the pendulum is too long, the clock will run slow. On the other hand, if the pendulum is too short the clock will run too fast.

In addition, the wrong leader length will also create problems with accuracy. You may or may not be able to correct this by raising the bob up or down. This is done by turning the rating nut below the bob.

If all else fails, a different leader length may need to be bought. Before shortening a pendulum it would be best to contact us to see if this is the best option. Cutting the pendulum is the last resort.

In Conclusion

As seen, this is not a cut and dry procedure. There are many factors that play into getting the correct combination so the clock will keep correct time. The correct leader is just one part of the whole process.

Sometimes all it takes is a leader that is a bit longer or shorter to correct an issue. There are also times where we have custom made leaders for customers.

Measuring is also important. No matter what situation it is we can surely find a solution. Don't ever hesitate to reach out and ask a question. Pictures are always good to send so we can see what exists now. Email is always the fastest way to contact us.

Clock Pendulum Top Hooks

Mechanical clock pendulum top hooks replace broken top hooks or to build a new pendulum. This is a nice alternative to replacing an entire clock pendulum if the top is broken or missing.

The top hook is the very top of the pendulum that will enable the pendulum to hang on the leader. To clarify, the leader is the 4 to 7 inch long bar that drives the clock pendulum back and forth.

What they fit

In fact, most of the top hooks here fit German post WW2 mechanical pendulum clocks. There are some top hooks that are for, or can only be useful on antique clocks.

It matters only that the pendulum can hang into the air onto the leader and be stable. Antique clock pendulums can use any one of these top hooks if it will do the job.

How to install

The top hook installation is by friction only. Bend the tabs over and use a punch and a hammer to secure it to the wood stick. Another way is to drill starter holes into the top hook and secure with screws or nails.

Rating Nut and Threads

A threaded rod with its rating nut. Is installed into the bottom of a wood stick pendulum by threading it into a pilot hole drilled into the wood.