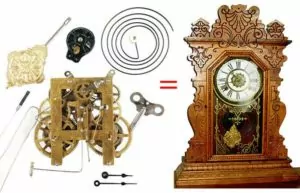

Antique American Clock Replacements

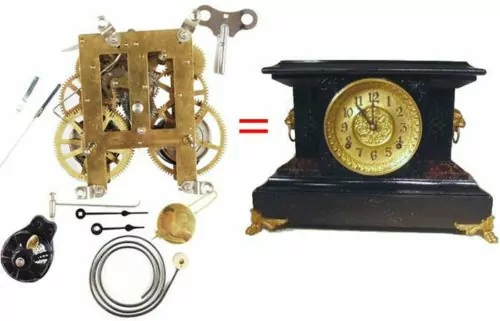

American clock movement Replacements made in India. These brass Antique American Clock Replacements are the same size as many early American pendulum clocks.

Therefore, they fit a variety of clock case styles made in that time period. An accurate reproduction of the American style movement with brass plates and oil sinks. These movements are also available in front or rear mount pendulums.

The overall quality is not the same as the antique units, however it will make the clock run again for years.

American clock movement matching

American clock movement matching is to replace the antique unit with a modern equivalent. Americans fell in love with the eight day time strike units back in the 1920's through the 1940's. These units had a mass reproduction.

Subsequently, they are the ones seen in Kitchen clocks, gingerbread clocks, and in thes shelf clock series of Steeple clocks. Mantle clocks, short drop wall clocks and the long drop units were also popular in this time period.

The American movements mass production

Most of these units had a bar style outer plates instead of a full brass plate. The winding arbor distances between each other and also the hand shaft were often the same. All of these units have the type of suspension with the feather steel at the top and a hook on the bottom.

They all run for 8 days on a single full wind with the clock key. All the pendulum lengths were cut back to 4 lengths due to the mass production of the American units. The hand shaft length from the front plate and all the way out to the end had some consistency in later years also.

Advantages of movements in a mass production

With consistency in the production runs, the India manufacturers began producing replacement units for American clock movement matching. The India movement even goes as far as calling them replicas but this is not 100% accurate.

Although they do the trick and get the clock up and running for many years, it's not the same quality. Brass quality is not the same from when it was back in the 20's - 40's. The brass is thinner and also the quality of the brass is not the same as it was.

We do offer these units despite this because they do serve well as far as just making the clock work for a bunch of years instead of giving up. When an antique clock movement has a repair that has gone wrong or already has 20 bushings in it or something silly, it may just make more sense to stick one of these in there instead.

What has to match

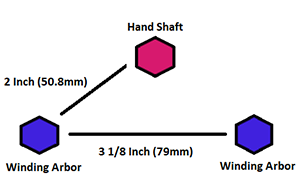

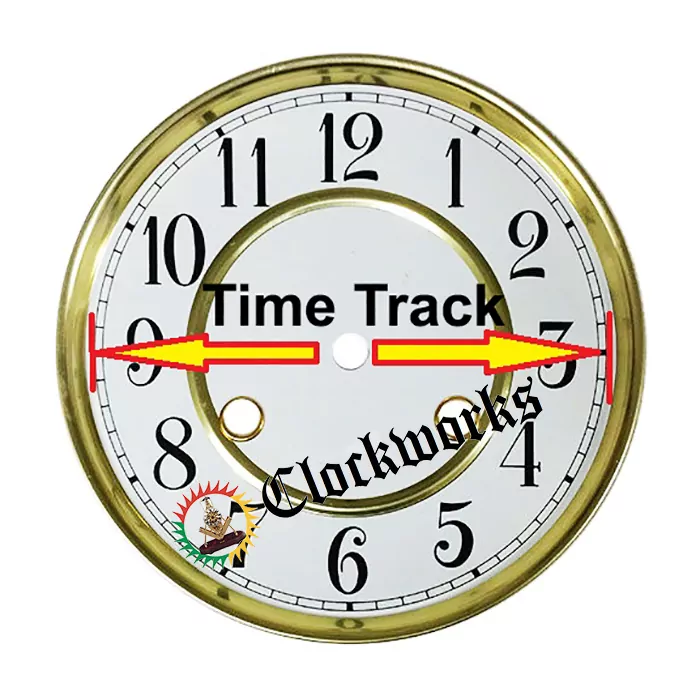

These bar style movements are in many antique American time strike units. Some measurements have to match. The dimensions of the winding arbors in relation to each other and also the hand shaft hole in the dial.

These will all have to match the below diagrams. This is to be sure it will fit the old clock dial and line up with the key holes to wind the clock.

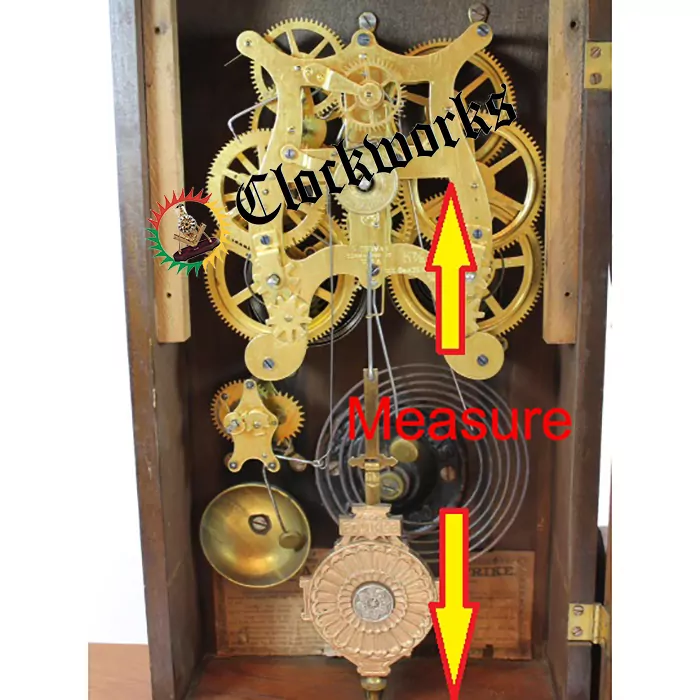

Then there is the hand shaft length from the front outer plate of the movement and all they way out to the end. The pendulum length is from the hand shaft and all the way down.

Matching the clock movement

Match the winding arbor measurements, pendulum drop and hand shaft length from the old unit to the new. The center shaft / arbor configuration will match up to many original dials.

The pendulum drop from the hand shaft and all the way down is available in variable drop lengths on some units. Please note the drop may fluctuate, the 13 inch drop unit may keep actual time anywhere between 12 1/2 and 14 inches.

American clock movement repair options

It's a shame when a clock is not able to operate for years on end. It sits for so long until one day it is just time to do something about it. For the antique American made clock to function again there are two main clock repair options.

Replace the movement with a modern reproduction made in India, or repair the clock movement.

Send in for repair

The movement is no longer in production and not available new. However one of the American clock repair options is to send in the movement for an overhaul instead. A clock movement overhaul or restoration does require the unit to be taken apart.

Repair process description

Inspection is done on every pivot and bushing hole to determine the best course of action. When a mainspring breaks there could be damage to the wheel train on the pinions and pivots. We use magnification to inspect all areas for damage.

Then we manually clean the clock parts with a cotton cloth and peg wood to be sure we get off all the old oil. In other words, the old oil solidifies and becomes an abrasive rather than a lubricant. This tedious process then entails pivot polishing and rebushing if it needs it.

After all this, it’s time for the ultrasonic cleaning machine with the clock cleaning solution. Then the rinsing and drying process.

The final step is to rebuild the clock movement piece by piece and then test it for a week. If it fails the testing process, all this is done again until it is right. These are the steps for the American clock repair option.

Replacement option

These Indian made movements are reproductions of some of the most common American antique units. Basically they are the last resort when the clock movement is beyond repair or has had many incorrect repairs. Take the clock movement out of the clock case and do some measuring to see if it’s a match.

Getting the replica unit

When looking at American clock repair options, there are many things to take into consideration. The first thing to measure is the pendulum length. This measurement is the American way not the German way. This means measure what is known as the movements “Drop”.

The drop is the length of the pendulum from the hand shaft all the way down to the bottom of the pendulum threads. The next thing to measure is the hand shaft length from the front plate of the movement all the way out to the end of the minute hand nut threads.

If these are both a match to the old unit, measure the clock movements winding arbors from left to right, center to center, and then from the winding arbor to the hand shaft hole center to center.

This will tell if the clock dial winding holes will line up on the movement just as the old unit did.

The American clock replacement units come in two ways. Just the movement or the movement kit that includes the key, gong, gong base, pendulum, and hands. It’s best to get the kit since it’s only $20 more and can be sure to have all needed with some spare parts.

American clock repair options summary

American clock repair options summary. It is best to preserve history and repair the antique unit whenever possible. However for various reasons this may not be practical.

There may come a time where the movement is not worth chasing and a replacement is better. The clock will no longer be a historical antique but it will be a functioning clock again.

Why replace an American clock movement?

Sometimes an American clock movement made 80 to 100 years ago is just too worn out. Replacing an American clock movement is the best option. We offer these units as replacements for when the old unit is worn beyond reason.

It will make a clock that has not run in a very long time work as it did before. The clock would lose any antique value but it may have had no value as a broken clock anyway. This is not uncommon to have clock damage that is beyond reason and the parts are not available.

Evidence of wear

The oil becomes a solid instead of a liquid and creates wear over time. When clock oil gets old, it gets solid and turns into an abrasive. Solid or semi-solid oil creates wear and is evident in the movement’s outer brass plate pivot holes.

Overall the clock has too much resistance in the movement to function under the power of the mainsprings. At the same time the pivots that spin in these holes get worn and oblong.

If a pivot is worn beyond reason, it requires re-pivoting which is costly and time consuming.

Mainspring trouble

When a mainspring breaks, it can cause the teeth on the gears to break from the impact. The mainsprings can also get stuck in a coil position from being wound up for many years.

In the clockmaker world we call this being "SET". The spring sets because of being wound up all the way and left in that position for 10 to 20 years.

Replacing an American Clock Movement In the end

The movements we offer on this page are made in India. These are sold as replacement units for the American movements that are too worn out to keep chasing. These movements last 10-15 years.

Unfortunately this is not as long a life as the old antique movements. The new movement from India is economical so swapping it out after a decade or two is advisable instead of considering a repair.

American replica clock movement

The American replica clock movement's on this page were made on the basis of the most common American units. There was a mass production of these units during the 30s and 40s.

Therefore they have a good chance of being a replacement for the worn out movement. By "time strike" units this means the clock tells time and also strikes.

Quality Comparison

The quality of the India made American replica clock modern reproductions are not the same. The antique American time strikes because the plates are thinner.

Due to brass going through the recycling process so many times it does not have the same quality as in the 1930's. However these serve well as a replacement for the American time strike unit that is worn beyond reason.

Life expectancy is about 10-15 years rather than the very long life of the antique clock movement.

Dial fitting

These American replica clock movements have a center shaft and arbor configuration that will match up to many original dials. In other words the holes in the current dial have a very good shot of matching up to one.

Chances are it will wind in the same places in the dial winding holes. Ideally you will not need to drill new holes to wind the clock or need to get a new dial face.

Measurements

Measurements you need to match up to be sure the American replica clock movement is compatible with what it has now.

- The length of the pendulum from the hand shaft to the bottom of the bob's nut threads

- The hand shaft length from the front plate of the movement and all the way out

- Winding arbor measurements in relation to the hand shaft so the clock can be wound in the same places through the dial.

American replica clock movement or kit options

The drop down menu will prompt to choose either the movement alone or the complete kit. The kit form comes with hands, key, gong, gong mounting base, and the pendulum.

Building an American antique clock replica

Between 1900 and 1945 the Americans made many clock movements with the same theme in common. The most common USA clock movements made during this era were the time and strike 8 day units.

Movements for this popular style are no longer made in the USA. India was able to come up with a replica movement. Once on the market they were a match for the antique American units in measurement and function.

So now it is possible to build a clock that is similar to the American antique clock.

Avoid building a mantle clock

The mantle clocks are not easy because of the dial / bezel / glass requirements that are unobtainable in the modern market. The more complex the dial requirements the less chance of obtaining such a thing in the modern market.

Mantle clocks such as Tambour style and Adamatine have dial / bezel / glass combinations that all fit together like a glove.

This increase in complexity makes it less obtainable from the start never mind getting into drilling the holes to wind it. Clocks with this style dial requirement is the least likely to come out successfully.

Nice clocks to build

Other clocks are good to build such as the kitchen units and the long and short drop clock kits.

Be aware these kits do not include the wood case or instructions on creating a case. We are only offering the internal components of these kits for the craftsman. Plans need to be bought elsewhere or replicate an existing clock.

clock case measurements to Building an American antique clock

Consider the depth and height requirements when planning to build the clock case for the new movement. Determine the depth with the hand shaft length in mind.

The height would be dependent on the pendulum length of the new movement and how much height overall it would take. Because these antique clocks were in a mass production it is not hard to find plans for a case.

The idea is to examine an existing case and add a personal twist.

Pendulum length

The drop is the pendulum length on the American movements, and therefore also the replicas. The drop is the pendulum length from the shaft that the clock hands go on, down to the very bottom of the pendulum rating nut threads.

This measurement is approximate and will vary with a lighter or heavier pendulum bob. Building an American antique clock replica case is best done by duplicating the basic measurements of an existing clock.

Hand shaft measurement

This is the length of the shaft that the hands go onto. Measure it from the front plate of the clock movement all the way out to the end of the minute hand nut threads.

This is important when creating a clock case and figuring out the depth to make it. Sometimes it is difficult to measure because there are gears in the way, however this is what needs to be done.

When planning the clock case, the best way to ensure everything will fit is to get the movement first. With the movement in hand, measurements can be taken to create the best wooden enclosure.

The dial to Build an American antique clock

Clock dials are not the same as what was in the antique world. The dial / bezel / glass combinations are pretty much obsolete. What is still on the market is modern looking instead of antique. It is advisable to stay away from clocks with this dial requirement.

Examples of this include mantle units and banjo clocks. Kitchen and steeple clocks are easier to build because we can supply a 6 1/2 inch dial that will work with the movement.

Clockworks can drill the holes in the dial to wind the clock to fit the arbor configuration. Dial grommets are put in the winding holes after drilling so the holes look pretty.

The dial that comes with the clock kit is optional to use. Of course the customer can use whatever dial alternative they choose.

Antique clock movement replacement ordering

Antique clock movement replacement ordering is done by matching up certain measurements. The new movement will fit when the pendulum length, winding arbor spacing, and hand shaft length all match the antique.

These clock movements measure the same as the ones that were in mass production in the USA from around 1900 to 1945. They are a nice replacement for many of the antique movements such as Sessions or New Haven and others.

The pendulum drop

The "drop" is a term to indicate the pendulum length. However, it is not the measurement of just the pendulum. The length is from the handshaft down to the very bottom of the pendulum rating nut threads.

Thus, this measurement is approximate and will vary with a lighter or heavier pendulum bob.

Hand shaft length

The hand shaft is the shaft that the clock hands are on. To match the measurements properly, the antique clock movement should have the dial and hands off the clock. The measurement of the entire handshaft is possible with the front of the movement accessible.

This would be from the front plate of the movement all they way out to the end of the minute hand nut threads. This measurement is important to match up because if wrong it can create depth issues.

Winding arbor configuration

The winding arbor measurements from one to the other and also to the hand shaft would need to match. This allows the clock to use the same clock dial it had in the past.

Antique clock movement replacement - Movement alone or clock kit

There are two choices, the movement alone for replacing a current movement or a kit that includes the movement / pendulum / hands / key / gong and base so can swap out everything but the dial. It may be best to get these additional parts just in case needing them.

Clockworks will custom drill a 6 inch dial with gold trim for the movement kit at no charge. This will be in the kit with the exception of the mantle clock kits. The reason for this is because the mantle dials are more intricate and no longer made.

American time-strike clock instructions

American time-strike clock instructions apply to replicas made in India as well. Subsequently, the name time-strike means the clock will keep time and strike at the top of the hour.

This section covers the basic installation for the time-strike and time only movements. However, American Time-strike clock instructions can be confusing. If not familiar with the clock parts or terminology, some of these directions may not be clear.

Consequently, if any questions, please email [email protected].

1. Setting the verge lock tab

This note is for front escapement movements only. Meaning the pendulum is in the front of the clock. If the movement has a rear pendulum then this information is not pertinent. Before mounting the movement, the tab has to be in place. Otherwise, the clock will not operate.

The tab goes over and locks the rocker pallets in place on the verge. The verge is the wire that whacks the pendulum back and forth as the clock tick tocks. It travels up to the rocker arm that engages with the escape wheel.

This is known as a verge assembly. The verge assembly sits on a post that sticks out of the movement.

There is a brass, or steel, metal tab that rotates up and down in order for the verge not to fall off. This tab goes onto the post that the verge rides on. The tab prevents the verge from falling off the front of the movement.

So with this tab in place, the verge should still be loose. In addition, the verge should be able to freely rock back and forth as the clock runs. This is important because if the verge cannot rock back and forth the clock will not run.

2. American time-strike clock instructions: Mounting the movement

First, center the winding arbors and the hand shaft onto the clock dial. This is an important step to mount the movement. Second, secure it in the same fashion as the old unit.

As a result, the movement mounts may need to be bent up or down to adjust it correctly. These are found in the four corners.

3. Winding the clock

The movement can be wound ALL the way up. That is to say all the way until it will not wind anymore. Moreover, it is a misconception that a movement can be “overwound”. This is not the case.

A full wind will allow the clock to run for 8 days. Anything less than a full wind and the clock will not last 8 days.

4. Adjusting the pendulum wire

The drop is the distance from the hand shaft down to the bottom of the pendulum. It is the pendulum length where the clock keeps proper time. This length is important to know for putting the suspension wire in place.

Notice that the pendulum suspension wire has the spring steel at one end and a hook on the other. The suspension steel end goes into the small slot of the suspension post on the movement.

This is location is near the escapement of the clock. The escapement can be seen on the front of the movement. The verge can be found under it to make the tick tock sound. Likewise, this is also the area that has the mounting post with the slot.

Slide the top of the spring steel into this slot. The suspension wire will hang on this post and then travel down through the hook in the verge wire.

5. American time-strike clock instructions: Adjustable bob installation

An adjustable bob has a rating nut with threads under the bob. Adjusting the nut allows for fine time keeping on the clock movement. Turn the nut to the right to speed up the time. As a result, this raises the bob on its wire. The opposite is true when lowering the bob.

Turn the nut to the left to lower the bob. Lowering the bob will slow down the clock. To install the bob, hang it on the loop end of the suspension wire. However, if this is a new installation, the loop may need to be made. As a result, this would need to be the proper length for the drop.

6. Hour hand installation

To install the hands, first place the hour hand on the shaft. This is the smaller of the two hands. It is also a friction fit. The hour hand tube tapers down. This may not be visible at first glance.

The hour hand will get tighter the further you push it down. Twist and push until the hour hand is as far down as it will go. Make sure it does not touch the clock face or anything else.

7. American Time-Strike Clock Instructions: Minute hand installation

The minute hand has an oblong hole. This oblong hole mounts onto the tip of the movement. This tip is also oblong and the two need to be in alignment.

The minute hand is then held in place with the minute hand nut. A pair of needle nose pliers may be useful to screw on this small hand nut.

8a. Clocks need to be put “In Beat”

All mechanical clocks that have a pendulum need to be put into beat. Ultimately, the most common scenario is the clock will run for 5 or 10 minutes, slow down, and eventually stop. Usually, people believe that the problem is due to the clock not being level.

It really does not matter if the clock is level or not.

8b. Why a clock would be "Out of Beat"

A clock can get out of beat for any number of reasons. If replacing the movement, you will need to put the new movement in beat.

8c. American Time-Strike Clock Instructions: The "Out of Beat" clock

Out of beat is a term to indicate that the ticks and tocks are not even. The tick and the tock need to have an even space with the same time delay.

8d. Attempts to avoid the inevitable

Antique clock owners who do not know how to put a clock in beat will sometimes have the case crooked for it to run. You can correct the beat by putting a shim under one side of the clock case.

The clock may run fine for years this way, however it is only a temporary fix. To clarify, if the mantle that the clock is on is not level, then the clock may have to run off level.

Whether it is level or not, it ultimately will have to be put into beat.

8e. Not all clocks are the same

Putting an early American time-strike unit into beat requires a different method than German clocks. This is also the case for the India replica movements. The suspension spring permanently attaches to a steel wire.

This goes from the escapement down through a loop in the crutch and verge wire. At the end of this suspension wire is a hook. Thus, the pendulum bob hangs on it.

8f. USA and replica beat setting

The pendulum rod mounts to a post on the movement. A loop in the middle of the pendulum rod whacks the pendulum back and forth. This brass wire loop is the crutch. It comes from the escapement on the movement.

When the clock is out of beat, you need to adjust the crutch wire. The adjustment is either to the right or left. Once bending this wire that comes from the escapement, listen to the tick tock.

Ideally the tick and the tock will be even. This means the clock is in beat. However, if it is isn't, keep adjusting the wire. Hopefully, the clock case will be level, however this is optional.

This concludes the American Time-Strike Clock Instructions. It is our desire to get the clock up and running quickly. Repairs and replacements can be frustrating, however it is quite an accomplishment.

Hopefully there is a better understanding of how and why clocks need to be in beat. Do not let common misconceptions prevent the clock from running. As stated previously, this can be slightly confusing.

This is especially true if one is not familiar with the various parts of the clock. Any questions, please do not hesitate to contact us. Email is always the best way to reach us. Our email address is [email protected].

Antique Mantle-Clock Movement Replacement

Replacement movement made in India for the USA made time strike movements commonly found in mantle-clocks. These are more like 10 year movements instead of the long lasting USA units made in the antique times. Best to restore the old unit whenever possible. This is an alternative if the repair is not an option.

Mantle-Clock Replacement Measurements

Match the measurements from the antique mantle-clock to this new one. Hand shaft to winder arbor distance, hand shaft length, winder to winder distance. If it is all a match it will fit just as the old one did and can be used with the old dial.

Antique mantle clock movement replacement

- Plates: 5 1/4" x 3 5/8"

- Min case width 4"

- Min depth: 3 1/2"

- Drop: 4 1/2"

- Hand Shaft 1 3/4"

Antique mantle-clock movement

Time and strike mechanical clock movement to fit many American antique mantle clock cases.

American clock movement replica

American clock movement replicas are not the same quality as the original but solves the problem. Thus, the clock will be working and striking as it should in a short time.

Of course, these movements are made in India but are close in size to many of the American time strike units made between 1900 and 1950.

Think of them as a 5 to 15 year disposable solution. These units are the best solution so as to not have to throw out a beautiful clock case.

Matching the clock movement

In the first place, the winding arbor measurements, pendulum drop, and hand shaft length all need to match the clock movement replica. The arbor configuration and the measurements are in the movement description to facilitate the ease of comparing the old unit to the potential new unit.

Likewise, the pendulum length is available in variable drops on some units. A pendulum drop is the pendulum length from the hand shaft all the way down to the bottom of the pendulum bob. Please note the drop may fluctuate.

In essence, the 13 inch drop unit may keep actual time anywhere between 12 1/2 and 14 inches. This can get a bit tricky so please email if there are any questions.

Clock movement only or the kit

The new movements are available to order in two different ways. The movement alone or complete kit with hands, key, gong with base and pendulum.

Clockworks will custom drill a 6 inch dial with gold trim for the movement kit at no charge. This will be in the American Clock Movement Replica kit with the exception of the mantle clock kits. Unfortunately, these dials are no longer in production.

Movement for a Ingraham “ATLANTA” model .

I’m L@@king for a replacement Movement

for this clock.

The movement in my

“ATLANTA” is stamped E INGRAHAM CO 4 BRISTOL CT USA 37 and

measurements are:

Plates: 5 1/8″ x

3.5″

Min case width 4.5″

Min depth: 2 .5″

Drop: 9 1/4″

Hand Shaft 1″

2” hand shaft to Winding Arbor

and Winding Arbor is 3 1/8”

I have not yet been able to find

a suitable replacement.

Thank you for any and all of your

valuable time!

John

No longer made. We can restore instead. Sending the movement alone in for restoration ?

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

My existing movement has a bottom of hour bell, do you have a replacement with this feature? Also the hand shaft length is 1-1/8″, all other measurements conform to your specs. This is a Sessions type mantle clock movement.

Sorry to say that one is no longer available new. We can overhaul this one if you like, we only need the movement alone sent in. We can tell you how to remove it and reinstall it, help you along the way. When its done and installed it will run for years.

We start with this =

CLEANING AND OILING FOR ONLY $200

We have the best and most expensive tooling, cleaning equipment, and cleaning solutions. There is no expense spared by us when it comes to having the best equipment. With this factor and 3 generations of clock repair expertise, you can rest assured your clock works will be in the best hands it can be in.

For this unit, we will take the movement in, unpack it, and then clean it and inspect it for $200. If it passes inspection, we will oil it and test it. If this is all that is needed that is all it will cost is the $200 plus the shipping back to you. The initial $200 is non refundable and is the fee for the cleaning, inspection, and oiling and testing only. We do need to be paid for our time on this even if the clock movement is deemed unrepairable for some reason.

Please let us know if you are interested in this service by filling out the repair form at this link, https://www.clockworks.com/clock-repair-service.html because it would be an absolute pleasure to get this one shiny and working again.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Do you sell a FLAT 5 inch diameter clock face for a mechanical mantle clock?

Yes, flat round clock glass at this link

https://www.clockworks.com/product/flat-round-clock-glass

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a clock with one of these movements. I am having trouble finding hands to fit the movement. Do you have a shaft size and carry hands for them?

The new one comes with two sizes of hands but do not have them loose and separate to offer

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Just what i was looking for, perfect.

Thank you for choosing Clockworks!

Looking for a replacement dial face for an 1898 Seth Thomas mantle clock very similar to the one with the lion heads on both sides.

That one is no longer available new. Best to get a junk clock case with a nice dial from ebay to fix that one

James

the perfect clock kit to help me restore my mantle clock

i need a movement that has an 80mm distance between winding arbors and a 45mm arbor-handshaft distance. i don’t see one on your website.

Do you have an existing movement>? What are the movement numbers?

James

Looking for a new movement, curious to know where this one is made…….. I have seen and dealt with cheap movements, and just want to make sure before purchase, that this is a quality movement with a good warranty……. Thanks in advance for your time and answer.

The India replacement movement is not the same quality of the antique units. However it does come with a 2 year warranty

James

India sir