Mechanical Chime Sequence ReSetting Instructions

Mechanical Chime Sequence ReSetting Instructions

The Westminster mechanical clock does not sound like Westminster when it plays? This would require these Mechanical Chime Sequence Resetting Instructions

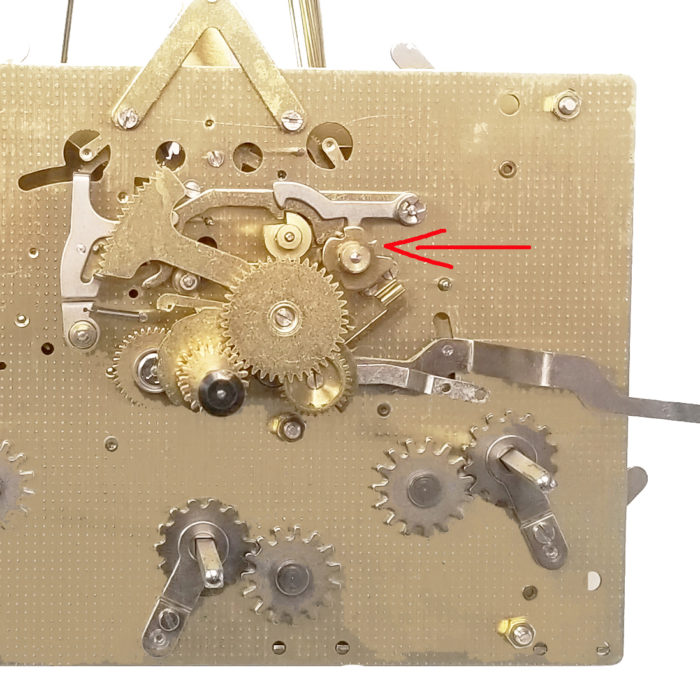

There is a cam with humps that graduate on the top right of the front plate of the movement. There are 4 lower portions with a small hump and the next one is bigger and so on. The smallest hump is the 15 minute mark where the hammers strike one at a time right down the row. This round brass piece with the humps on it, controls when the movement is to stop chiming.

The small hump represents the first quarter as this is the shortest chime of them all. The hourly chime is the longest hump as it is the longest song of the four quarters. This same large hump has an even higher hump at the end of it. This will drop the saw tooth rack to fall. So when it’s done chiming the top of the hour, it can start striking out the hours. This is with the help of the saw tooth rack counting system.

Run the chime by turning the hand (mounting with the nut is not necessary, just put it on there so you can turn the hand shaft and make it chime). Notice the cam with the humps spinning and wait until it gets to the end of the smallest hump and stop the gear train from moving with your fingers and hold it. This is the end of the first quarter, the first 15 minute mark. Now set the hammers to match this from the back of the movement.

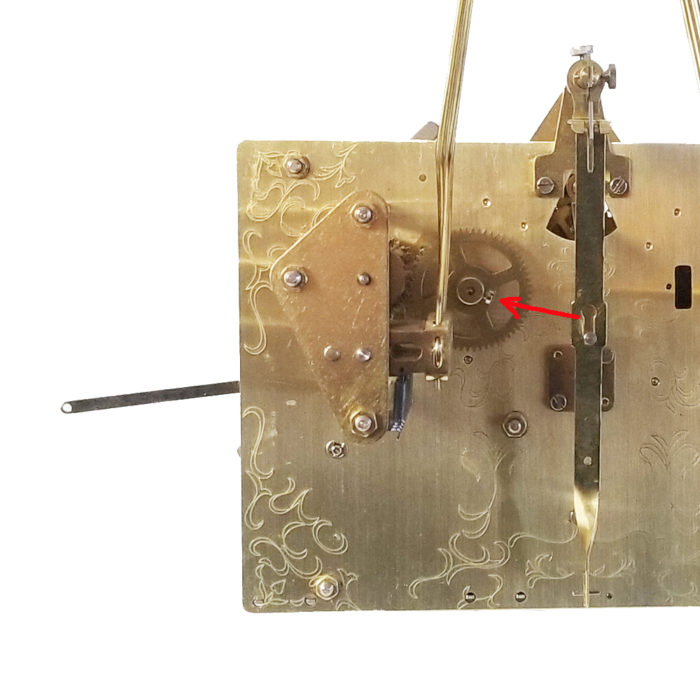

Please now look at the back of the movement. There is a big gear on the OUTSIDE of the back plate of the movement. It has a set screw but loosening it is usually not necessary. Anyhow, while turning this gear and at the same time not letting the gear train run, it will turn around and move the hammers until the hammers strike each one time right down in a row, representing the end of the first quarter.

Use your left hand and put one finger on the top of the left gear train as to not let it spin. At the same time, use your right hand and turn this gear on the back of the movement until that very last hammer drops down after the 1-2-3-4-5 hammers drop in a row.

With this set to the position where the last hammer drops, tighten that cam (this explanation was in the first paragraph) so the bar that rides the cam is in the down position just after the smallest hump on the cam. Now the chimes are set correctly.

↑ Back to top

i have thoughtlessly pushed the circular cam hammer activating rings for the hammers for a Forestville Hamilton 1895 Barrister 3 tube Mercury pendulum 4 selection switch: Silent, Whittin-, St. Michael, Westmi- chimes out of proper position. No matter why, the thoughtless movements were not recorded from the original positions now the individual tunes are jumbled/altered as of course the cams don’t move/release the hammers in the correct sequence soooooo U can imagine my pleasure in getting the clock freed up to keep time within a seconds over a week but the quarter, half, three quarter and hour chimes are no longer of course the chime tunes as noted above. The hours hammers are correct as I moved the cam ring hammer activators only on 4-5-6 ? front cam rings’ The circular cams seem to move easily in a clockwise direction by gently pushing the bottom of each cam ring however I suspect I may have to take the works out to fully view the rings it. I can tinker and have rebuilt a 59 MGA Transmission and other more or less complicated devices. I have broken down many items to ressurect them but I am no Clockmaker!! if all the circular cam lobes can be moved and discerned from the side access port doors Hallelujah! However I must go about’ heaven forbid removing the clock works from the clock case, I must first have a proper position diagram illustration detailing the proper location the cam ring hammer release lobes must be in?. Is there a Proper clockmaker in the St. Petersburg, Florida area 33708 who could handle this as my fellow has long ago moved. The works were totally rebuilt bushings replaced etc. 5 years ago & kept properly oiled so condition isn’t the problem my ph is 727-488-5280

From here all we can do is offer to take it in for cleaning and inspection. Although work was done, it does not sound like it was a great job if your having issues in 5 years time only. We restore clocks the right way, no short cuts.

Interested?

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a Howard Miller Arendal grandfather, after leveling, and calibrating the pendulum, I’m trying to get the chimes working.

Is this similar to what you explained above?

Is this one cable driven or chain driven?

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have 1161-053 3 chime movement on my 30 + year Howard Miller Grandfather clock. It chimes with a slightly inaccurate chime and will not stop chiming unless I turn it to the silent position. It’s been like this for at least 20 years. I haven’t bothered to have it repaired or replaced. I’ve talked to a clock repairmen and his comment was due to its age it would be best to replace the movement. The time part of the clock works normally, but it’s been silent for many years. Now I would like to have it working with all three chimes. I would appreciate any suggestions you might have.

Hi,

Although the clock maker is correct that the unit is due for replacing from the age alone, here are some things to check

https://www.clockworks.com/posts/grandfather-clock-chimes-forever-correction

When your ready to swap the movement out, please order the 1161-053 from this link, if your clock is chain driven.

https://www.clockworks.com/product/new-1161-053-clock-movement-by-hermle

You will not need to hire anyone to put this in, comes with instructions and support if you were to need it.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

How do I make the chimes louder on my chime clock. I can barely hear them?

The hammers are to be bent approximately 1/8 of an inch from there chimerods. This way they will not thud or double

hit. The volume will vary depending on if you have the clock on hardwood or a rug or against the wall or not.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

good description but did have to loosen screw, now chimes in correct sequence thank you

Glad it is all set now

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com