Please view these information tabs to learn about our Mechanical Clock Chimeblock and Rods

Why we offer only the complete chime-block

We now only offer the complete clock chime-block and rods. The rods are a press fit into the chime-block by machines and it is difficult to get a single rod out. Other times there are threads that go into the block but have such a secure tight fit, you cannot remove them.

Trying to do so would result in more rods breaking. Also there are various threads on the rods that are the replacements and it can create much confusion. It is for these reasons that we now offer the complete clock chime-block and rods.

Overall, it is a tricky thing to get the correct thread size for the individual rod in a chime-block and rod set and have it fit perfect. Not to mention, when the chime-block rod is not the correct size, often enough it gets sent back. Then we get into the situation of trying to swap it out over and over.

Moreover, all of it eventually ends up being a return for a complete chime-block and rods set. So, in the long run it is best to just get a new chime block and rod set from the beginning. That will save a lot of time and frustration.

Chime-block and rods volume

The volume of the clock chime is not alterable by means of the chime-block and rods or the hammer adjustment. These parts have nothing to do with making the clock louder or softer. The only thing that can make the clock louder or quieter is to move the clock case.

If the clock is on a hard wood surface it will be louder. A rug will be quieter. The proximity to the wall can also alter the sound. It has nothing to do with the chime-block and rods.

Clock Chime Block Styles

The first step in purchasing a new chime block is to determine the chime block style that is in the clock.

The Styles are side, bottom and back strike.

Figure out which style you need. Then, count how many rods are in the chime block. Measure through the chime block to get the length of the longest rod.

Correspondingly, find this information on the drop down list for the correct chime block and rods.

Bottom Strike Style A

Chime block style A For bottom strike and side strike units.Side Strike Style B

Chime block style B For side strike units. Occasionally, you can also use this for back strike diagonal Westminster units.

Back Strike Style C

Chime block style C is for floor clock models (and some wall clocks) with two rows of hammers on the back of the clock movement.

Chime sound in Clock Chime Block Styles

No matter which Clock Chime Block Style you need, there has to be some adjustments made. If the clock chime does not have a clear, crisp tone, do not panic. It could just be a matter of adjusting the hammers on the rods.

The hammer heads are on wires which are meant to be bent. Do this with your fingers, while the hammer head is down.

Just bend the wire that the hammer head is on, one at a time. Keep the hammer head about 1/8” from the rod when it’s at rest. In other words, in the up position. Bend one at a time.

Then, lift and drop it to see if there is a nice crisp tone. Subsequently, do this right down the line with each hammer on whatever chime block style. Make sure each one has a nice tone. In the long run, the chime will sound perfect.

Why does Chime Hammer Positioning Need to Occur

Mechanical clock chime hammer positioning is easy to do. It only involves bending the hammer head wires. Upon the initial installation, this was done by the clock maker as well.

When replacing a clock movement you need to bend the chime hammers to the chime rods. This is why the hammer heads are on bendable wires.

They are meant to be bent into the perfect position. It is not uncommon to bend them an inch this way or that way. The clock movement will not have the hammers in the perfect spot to make the correct sound when hitting the rods. This is why chime hammer positioning is so important.

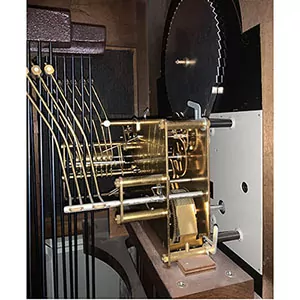

Clock Chime Hammer Positioning

A mechanical clock movement has hammers that need to be bent into their final position. The correct clock-chime hammer position needs the tops of the hammer heads to be about 1/4 inch down from the chime block.

The hammers need to be 1/8 inch away from the rod. This would be when it is at rest. In other words, bend the hammer wires so the head is 1/8 away from the chime rod. This spacing between the head and the rod is so it will not thud or double strike.

Tuning the mechanical clock chime

Repeat this process for each wire, one hammer at a time, down the line. Continue in this manner until you can lift and drop the hammer to create a crisp sound. If each hammer head is done this way the clock will have a nice song in the end.

Often a customer will say the sound is not correct. This is due to improper hammer positioning. When performing the above directions correctly the sound is beautiful.

Positioning the 340 / 341 series

The 340 and 341 Hermle clock movement series went through a change in the hammer wires. The hammer heads were on wires, but now they are made on flat bars. The positioning is still the same, however it is a little more difficult to bend them.

The hammer head is on the skinny end of the bar. The bar gets wider as it goes back toward the roll pin.

With needle nose pliers, bend this bar where it goes from skinny to wide. The overall assembly will be slightly higher from the chime block. That is, if you are swapping out the movement with the older style wire hammer head rod.

It is an option to raise the entire chimeblock with a shim to help with this. It is not an absolute requirement. Bending the hammer arms are usually sufficient.

For a clean crisp chime sound

Adjust the hammer wires

Should be about 1/8 away at rest

Sometimes they are bent to the extreme

Chime Block

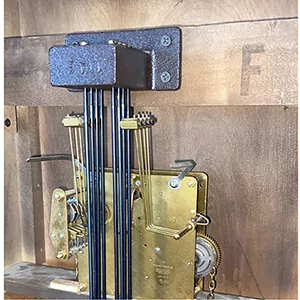

This is a Chime Block for a movement that has a bottom strike. The length is the longest rod within the block from end to end. This mounts to the bottom of the clock case so the hammers can chime the song. This means the hammers of the movement will be on the bottom of the movement.

The block plays a crucial role in the chiming mechanism of many clocks, particularly grandfather clocks. This block sits at the base of the clock movement with bolts that secure it to the clock case. When the clock strikes the hour, hammers within the movement strike the bottom strike chime block, producing a deep, resonant chime tone. Traditionally made from durable brass for optimal sound quality and longevity. The design and material of the block significantly impact the overall chime sound of the clock. Bottom line is that the bottom strike chime block is a vital component in the chiming mechanism, producing the deep, satisfying chime that signifies the hour in many clocks.Please note, the mounting bolt pattern may or may not be the same as the old. There is a chance new holes need to be made to mount the new chime block to the clock case. However this is not a frequent occurrence.

Additional information

| Weight | 3 lbs |

|---|---|

| Rods | 2 Rods (7in longest), 3 Rods (6in longest), 5 Rods (7 1/2in longest), 5 Rods (9 3/4in longest), 8 Rods (7in longest), 8 Rods (9 3/4in longest), 9 Rods (8in longest) |

Clock Chime-Block Bottom Strike

| Rods | 3 Rods (6in longest), 5 Rods (7 1/2in longest), 5 Rods (9 3/4in longest), 8 Rods (7in longest) |

|---|

I have a Herman Miller 340-020A. The two longest rods are broken off. I would like to order a set and may end up putting all rods into my old block.Do the Chime Rods in the “Clock Chime Block Bottom Strike” have a 6.5 mm Threaded End by which they are mounted into the block, or are they Press Fitted?

They are screwed in, not sure if 6.5mm.

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

Hello , I have an Ansonia Sonia #13 mantle clock that plays the westminster. Is there a chime bar available for that case ? It’s a tambour style case .

Maybe. Please email a pic of the back side of the clock with the door open or off. Clockworks@#clockworks.com need to see what mounting style

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Best service I’ve had in a while.

Iam glad it worked out. Great Job !

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

have a Seth Thomas 1977 regulator clock cat#2306 ( 2306-000) name railroad regulator 687-123 9-26-77 on clock mechanism A036-012-820 run by1 D cell battery. has a 2 rod Bim Bam side strike if you use the hour hand it will gong on the hour but clock will not advance time. and pendulum stops after you start it swinging. Is a replacement mechanism available for this clock. My mothers clock wants it working in the worst way, 87 years young . Any help would be appreciated pricing and availability if possible.

Thank you

John

They do not make that one anymore with the electromechanical bim bam strike. ITs all just battery operated these days but the sound is best.

For Chime Movements or Pendulum Movement See this link

https://clockworks.com/clock-movement/quartz-specialty-clock-movements.html

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

What is the best way to find the Chime Block need for my Howard Miller Clock. The part is missing from the clock.

Only need to match it up by looks, how many rods, and the approximate length of the longest rod

https://www.clockworks.com/?post_type=product&s=Chime+block

James

I’m looking to replace a 2-bar chime for an older Sessions clock, bim-bam type.

My current rod lengths are 9 and 10 inches – including the depth of the cast block.

The screw holes for mounting are spaced 1 1/2 inches apart.

Are dimensions available for the chime block that supports two bars?