Clock Chime Hammer Positioning

Why does Chime Hammer Positioning Need to Occur

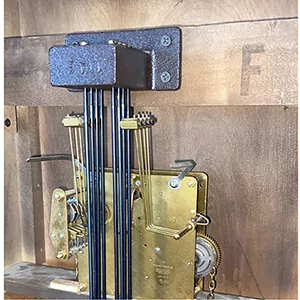

Mechanical clock chime hammer positioning is easy to do. It only involves bending the hammer head wires. Upon the initial installation, this was done by the clock maker as well.

When replacing a clock movement you need to bend the chime hammers to the chime rods. This is why the hammer heads are on bendable wires.

They are meant to be bent into the perfect position. It is not uncommon to bend them an inch this way or that way. The clock movement will not have the hammers in the perfect spot to make the correct sound when hitting the rods. This is why chime hammer positioning is so important.

Clock Chime Hammer Positioning

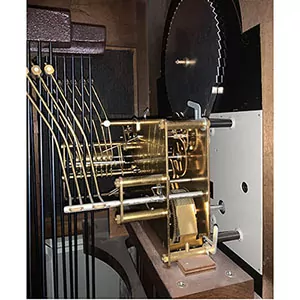

A mechanical clock movement has hammers that need to be bent into their final position. The correct clock-chime hammer position needs the tops of the hammer heads to be about 1/4 inch down from the chime block.

The hammers need to be 1/8 inch away from the rod. This would be when it is at rest. In other words, bend the hammer wires so the head is 1/8 away from the chime rod. This spacing between the head and the rod is so it will not thud or double strike.

Tuning the mechanical clock chime

Repeat this process for each wire, one hammer at a time, down the line. Continue in this manner until you can lift and drop the hammer to create a crisp sound. If each hammer head is done this way the clock will have a nice song in the end.

Often a customer will say the sound is not correct. This is due to improper hammer positioning. When performing the above directions correctly the sound is beautiful.

Positioning the 340 / 341 series

The 340 and 341 Hermle clock movement series went through a change in the hammer wires. The hammer heads were on wires, but now they are made on flat bars. The positioning is still the same, however it is a little more difficult to bend them.

The hammer head is on the skinny end of the bar. The bar gets wider as it goes back toward the roll pin.

With needle nose pliers, bend this bar where it goes from skinny to wide. The overall assembly will be slightly higher from the chime block. That is, if you are swapping out the movement with the older style wire hammer head rod.

It is an option to raise the entire chimeblock with a shim to help with this. It is not an absolute requirement. Bending the hammer arms are usually sufficient.

For a clean crisp chime sound

Adjust the hammer wires

Should be about 1/8 away at rest

Sometimes they are bent to the extreme

↑ Back to top

Hello. I have a Emperor clock with a Jauch 77 movement. I can’t figure out how to get the notes to play in the right sequence. To explain, let’s start with the hourly chime and consider that it’s grouped in the four lines of notes (for the four lines of the prayer).

On my clock the quarter hour plays the last line of the hourly chime.

The half hour plays the quarter hour chime and then the first half of the half hour chime.

The three-quarter hour plays the last line of the half-hour chime and the first two lines of the three-quarter hour chime.

Finally, the top of the hour plays the last line of the three-quarter chime and then the first three lines of the hourly chime. Then the cycle repeats.

Is this something I can fix?

These are 30 year units at best, yours is over 43 years old. So it was some good luck with that one. Time to restore or replace, replace is less cost, quicker, better. See the Jauch 77 conversion kit at this link for more info =

https://www.clockworks.com/product/jauch-pl77-clock-movement-kit

If still wanting to chase this one, please see this link on the subject

https://www.clockworks.com/posts/mechanical-chime-sequence-resetting-instructions

James Stoudenmire

40yr Clockmaker

Author of Clockworks.com

Hello Mr. Stoudenmire, is there a manual and schematics available for a tempus fogit HERMLE 451-050H, 94CM/66, all the you tube videos really don’t described my issues, the middle weight turns the clock, but the 2 outer weights are not working, please any guidance? thank you;

This is the same as saying the clock is not chiming. If it does not chime it will never strike. The center weight is just for the time and pendulum to swing.

Be sure the clock’s silent lever is in the down position. This lever is at 3oclock on the movement. This is chime ON.

The chain cant be rubbing anything in its path like the seat board. Should be ratchet wheel straight to the weight, not rubbing anything.

Is the hammers hitting anything in its path when they move? If the hammers are rubbing the back of the clock case, or if there hitting or rubbing against each other, the clock will hang up and not chime

The heaviest weight on your right as you face the clock? The chime weight is the heaviest weight out of the three and goes in this position.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a 38-year-old Baldwin Grandfather clock. The rods that make up the middle of the pendulum all fell off. I just went to wind it one day and they were all lying on the floor of the clock. Can you please give me some suggestions on how to put it back together and make sure it doesn’t happen again?

Thank you very much.

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I found a metal sticker with the serial number and model number.

Hi James, My grandfathers wedding present was a Grandfather clock! Made by J E Caldwell around 1905 in Philadelphia I think.

The hours chime correctly but the 1/4 hours are out of sync. The (4) quarter past chimes should all be in decending order.

I have twice previously lifted the register above the spiked cylinder and reset the sequence correctly, but what causes it to go out of sync again?

Kind regards

Patrick

No telling from here the issue because in 1905 there was not much standard in the GF clocks and much strange designs.

If you would like to send it in for restoration we can figure it all out in the duration.

Sending in ?

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

My Dad – now long gone – made four beautiful clocks for his wife and 3 kids. All have stamped Mason & Sullivan 451-050H 94cm within. On one of them, a hammer (2nd in from the ,echanism backplate on the left side) fails to sound only during certain sequences. When it fails, the hammer is ‘lifted’ and released but it doesn’t seem to fully strike the rod or perhaps it strikes but stays in contact with the rod. Since that hammer works in other sequences, it doesn’t seem to be a case of ‘need to bend the hammer wire’ but rather something different about that ‘tooth’. Visually that ‘tooth’ looks no different than any other. I have marked the failing ‘tooth’ on the rotating plate with red marker and can predict when the hammer blow will fail to sound a note. What would cause this and how to fix or replace? Thanks for any guidance!

Please see this link on how to date the clock movements

https://www.clockworks.com/posts/hermle-movement-date-codes

If the clock is 20 years old there is no point in chasing your tail with these units, they are 25 year units at best.

The new one is less cost than even a routine cleaning on these, never mind if it really needs work.

Its just best to swap them out all around, you get it trouble free in days instead of months and at a fraction of the price. There is no way to restore a clock movement better than it comes new.

If this sounds good please see this link

https://www.clockworks.com/product/new-451-050-clock-movement-by-hermle

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

The hammers are to be bent approximately 1/8 of an inch from there chimerods. This way they will not thud or double

hit. The volume will vary depending on if you have the clock on hardwood or a rug or against the wall or not.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

One of my chimes sounds like a dud. What could that be? (Howard Miller clock). I haven’t started it in years. just started it up. Keeps time well but one note is flat. The hammer strikes but it’s just a dud sound.

See this very same page for the solution to that issue. Hammer heads are meant to be positioned approximately 1/8 inch from the chime rod.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Is this 1/8” spacing also true for the strike rods at rest?

Yes

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I purchased a Jauch 78 and just finished the installation. The clocks works nice, but the chimes sound weird, the hammers are aligned with the wires, but the notes do not match Big Ben. The old clock movement played the notes correctly.Do the wires/bells go from high note at the front and low note at the back or the reverse? The existing rods have a strange order. can these be re-positioned in the block?

In rare situations, it is required to reverse the order of the rods on the chime side. The rods will come out with a big flat head screw driver. Hopefully.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

The pendulum hits the chime rods when it swings. Should I move the chime block further back so the rods are completely behind the pendulum? Can the pendulum be positioned so it swings between the rods? I’ve attached a picture that I hope is helpful.

Please see this article on a similar issue

https://www.clockworks.com/posts/451-1151-high-bridge-suspension-post-length-issue

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Thank you for explaining the chime hammers positioning, I think the bigger problem is that the suspension post actually hits the first chime rod on the right side. If you look at the positioning of the chime box, it is slightly offset to the left of the center in the case. In order to have the dial holes line up with the movement it should be in the center. But then the suspension post hits the chimes.

Please see this post on the subject

https://www.clockworks.com/posts/451-1151-high-bridge-suspension-post-length-issue

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a Seth Thomas Tambour mantel clock with 124 mechanism and Westminster chime. The chime hammers don’t play the 1/4 hour correctly. Can this be fixed by repair or do I need a new hammer mechanism.

It can certainly be corrected with restoration of the clock movement. No new parts are available for the ST 124 clock movement except for mainsprings. However we have antique parts and the ability to custom create parts as well.

It is not inexpensive to restore the movement, but that one is high value and sought after.

More on restoration

https://www.clockworks.com/clock-repair-service.html

More about us

https://www.clockworks.com/about-clockworks.html

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Greetings from Mexico. My grandfather clock fell during and earthquake. Now, the hammer wires were desaligned. The issue is that they moved like 3/4 of an inch. On one side there is a screw to realign the hammers, but in the side that has the music wheel, there is no such mechanism.

This is a Henry Miller model 610-864.

The movement is mounted on two screws. Seems the screws are not tight and the screws shifted and so did the movement. Best to act as if removing the clock movement and retighten things when your in there.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

When setting the Chime Block where should the Hammer strike on the Rod?

Hi,

Please read about adjusting the hammers at this link

https://www.clockworks.com/posts/clock-chime-hammer-positioning

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hi James. We are going to be moving our grandfather clock to a new home. We understand the process; however, do we need to secure the chime hammers? If so, what is your recommendation?

Thank you,

Melissa

No need to secure the chime hammers, they can make all the racket they want and it does not matter.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I am looking for clock hammers, mine are cylindrical and a bit longer then those sold today. It is used in early French Odo clocks with double chimes.

Hi, We have only these to offer

https://www.clockworks.com/product/clock-chime-hammer

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a warmink mantle clock. I just had it in for servicing. Just recently it quit chiming. It was wound and would keep perfect time but didn’t chime. I took it back in and the gentleman told me the chime mechanism had gotten “hung up”. Now two months later, it is doing the same thing. Keeping perfect time, but not chiming and acts again, like it’s hung up or stuck.

Can you offer any suggestions?

Thank you

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

My Grandfather clock will only chime when I apply weight to the right weight. How do we fix this?

What are the numbers off of the back plate of the clock movement itself? If it is hard to get to, usually you can stick a cell phone up behind the movement and get a picture of the numbers. Or through the side access panel if there is one.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I just purchased an electric mantle clock from the 1930’s and the hammers are too far from the rods. From the shape of the hammer arms, they don’t look like they’re easily bendable in that direction. Is adjusting them different?

Sometimes a shim underneath the clock’s chime block is needed.

Usually two screws underneath the clock case takes out the chimeblock

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a lantern clock circa 1750. Still runs perfectly, but the chime hammer does not strike fully. The mechanism also squeaks. Pls advise as to how one should correct this. I live in a very dry semidesert environment. Marina

It sounds like it needs clock oil https://www.clockworks.com/product/clock-oil-with-oiler smallest drop where ever one thing rubs another

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hi I have a Seth Thomas Northbury mantel clock with Westminster chimes and the hammer closest to the door isn’t 1/8 an inch above the chime rod. Any advice on how to fix it to match the other hammers to be 1/8 inch above the chime rods?

Down the line, and one hammer at a time, repeat this process. Continue in this manner until you can lift and drop the hammer to create a crisp sound.

If each hammer head is done this way the clock will have a nice song in the end. Often a customer will say the sound is not correct. It is because of improper hammer positioning that this occurs. When you perform the above directions correctly the sound is beautiful.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hammers are on wires as they are meant to be bent into position.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hi. I have a Becker mantel clock, Westminster chimes etc. The hammer tips are old, worn, and need replacing. The chime sound has become less ‘mellow’, more strident of late. Was thinking of replacing the tips with leather or perhaps nylon. Would there be an appreciable difference in tone with the two materials?

Not much really. Best to put the clock on a hardwood floor and tune each hammer head to sound good

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hi,

I bought an Edwardian long case grandmother pendulum clock on an online auction. It was sold as not working but now I’ve put the clock in beat and adjusted the hammers for the Westminster chimes it’s working well.

I only have one problem. When the clock strikes the hour it’s very quiet. You can just about hear it. I adjusted the hammer and the tone is better and it’s slightly louder but very quiet for such a large clock. There isn’t anything on the mechanism like fabric being to muffle the hammers.

I know the mechanism isn’t complete as it looks like it has a silent feature which isn’t connected and also the moon dial mechanism is missing.

Thanks

Becky

Why Chime Hammer Positioning is required

Mechanical clock chime hammer positioning is easy to do, and only involves bending the hammer head wires. Upon the initial installation, this was done by the clock maker as well.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

The pendulym is hitting rod hammers & keeps stopping

Sometimes that can be fixed with the feet on the bottom of the wooden clock case. The leveling from front to back does not have to be dead on or anything. This may correct the issue

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Pendulum is hitting rid banners and keeps stopping

Can someone give advice on a matter of my chime hammers . It is a Franz Hermle mechanism, the hammers free play when I move the Clock. The chimed are terrible. Everything is oiled. Is there supposed to be play on the hammers or can I tightened these up or is it a new spring of a kind.

Thank you

A mechanical clock movement has hammers that need to be bent into their final position. The clock-chime hammer position should be so the tops of the hammer heads are about 1/4 inch down from the chime block . The hammers need to be 1/8 inch away from the rod when at rest. In other words, bend the hammer wires so the head is 1/8 away from the chime rod. This spacing between the head and the rod is so it will not thud or double strike.

Tuning the mechanical clock chime

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Down the line, and one hammer at a time, repeat this process. Continue in this manner until you can lift and drop the hammer to create a crisp sound.

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

Hey Bill

I have a smiths enfield mantel clock. What’s the best thing to use when cleaning a hammer head. Should you ever clean the chime or leave that part well alone please?

Thanks.

Simon

Just leave it be usually

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com

I have a wall clock with 3 chime bars.if I adjust them so they work when it strikes they fall back and dont hit sound bars.it seems the drive cam is too close for the hammers to fall down

Please email me a pic, I do not understand

James Stoudenmire

30yr Clockmaker

Author of Clockworks.com